Over the last couple months, we’ve had the pleasure of testing out the Roest sample roaster. We were excited for many reasons, mostly the obvious: new toys are the best! The main driving factor, however, was our recent auditing of quality control practices. We, as a company, are always looking for ways to improve and refine day-to-day operations. This new toy was just the cherry on top.

One thing that was immediately evident after only 5 test roasts: the machine was remarkably intuitive and felt natural to use. Not only that, the roasts that resulted were easily an entire cup score higher than we had expected.

Be advised: the point of this snippet is not to write a commercial for the Roest sample roaster, this is just to illustrate that we obviously had some low-hanging fruit in terms of improving our Quality Control. Vic Scutari (Quality Control & Roasting Assistant) and I have just about two decades of roasting experience between us, so it’s safe to say that we were floored at just how drastic the results were.

Our focus during this particular session was the development time of sample roasts. We felt that we had a very consistent profile pre-first crack, and were getting solid, structured coffees as a result. But we also noticed a few small inconsistencies in scoring— depending on where (physically) the coffee was being cupped.

All sample roasts for North American partners are done in one location: Massachusetts. Then they are pre-cupped prior to sending to ensure accuracy. At any rate, mixed results were coming in (particularly when the coffees are being cupped on the west coast). We finally agreed on having two separate approaches for the different markets, but the question still remained: What exactly was the proper amount of development?

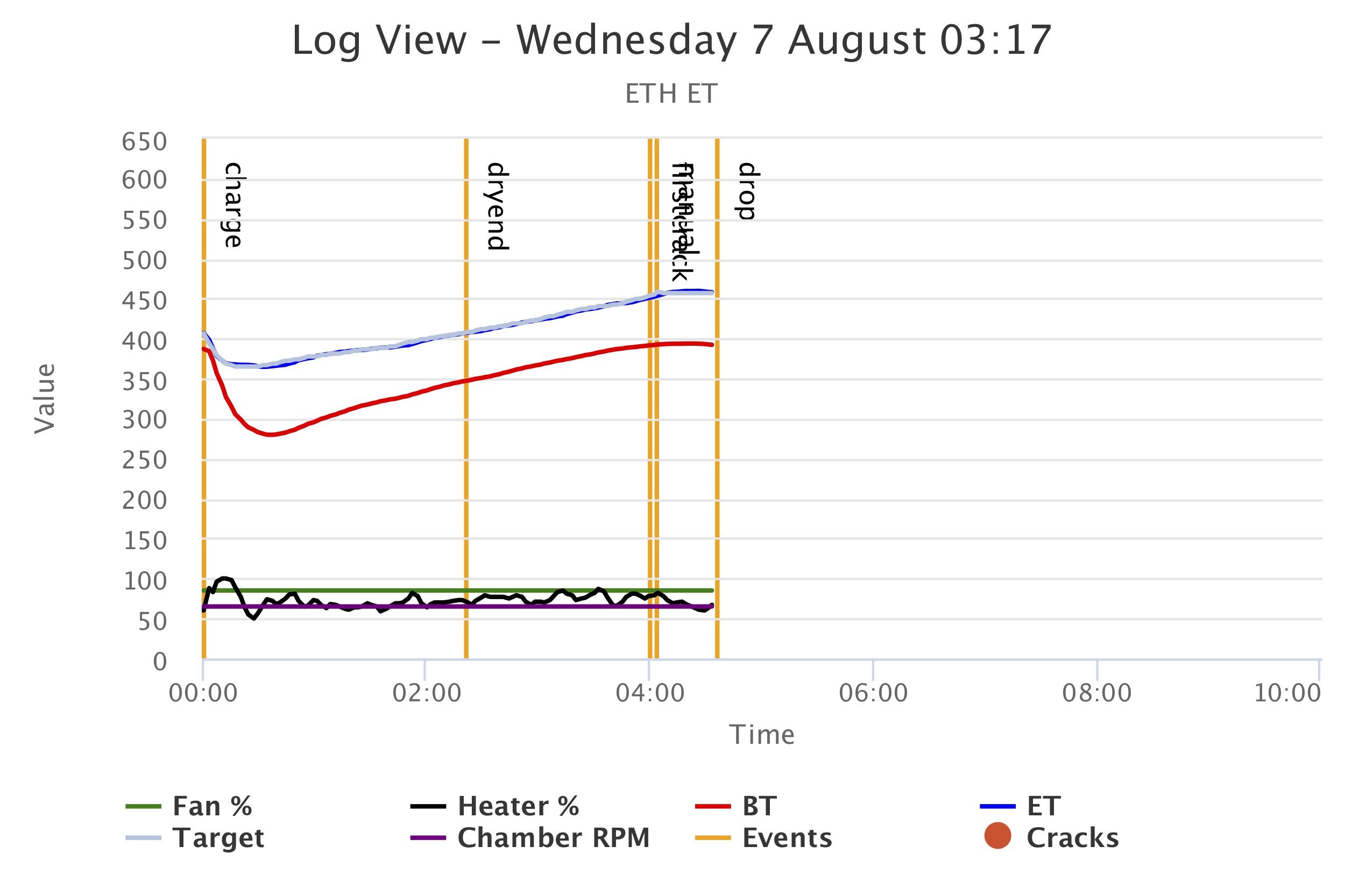

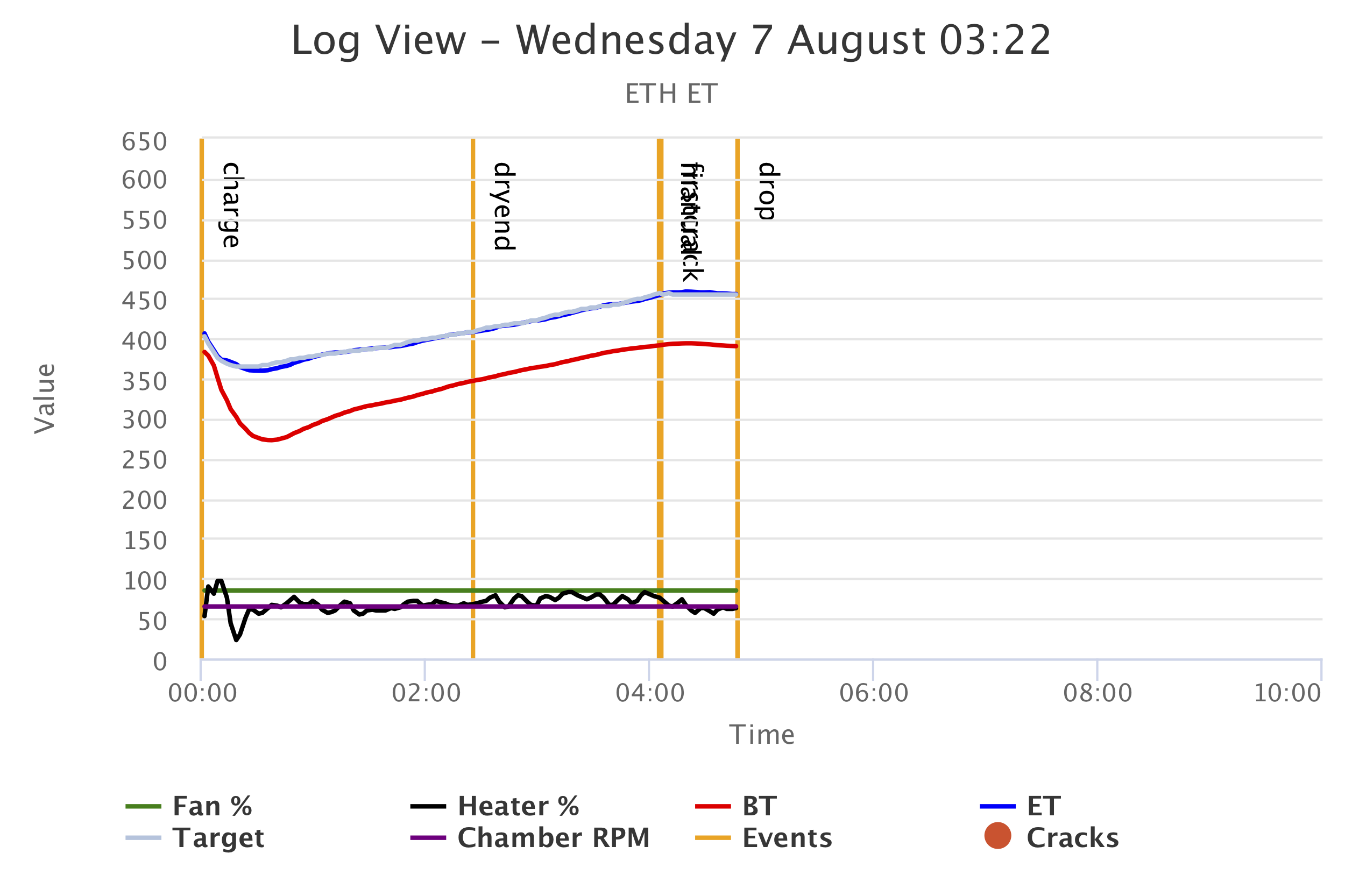

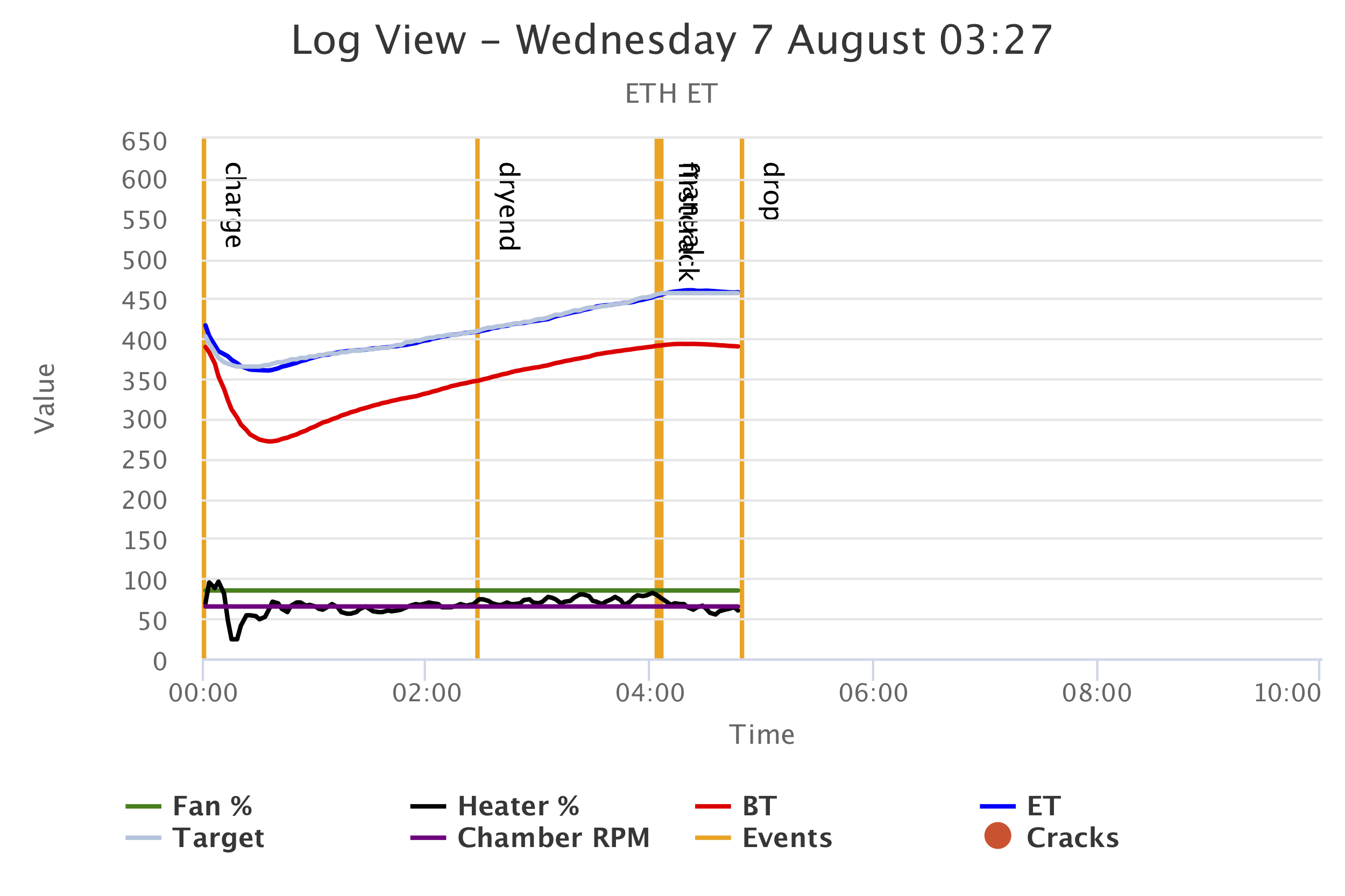

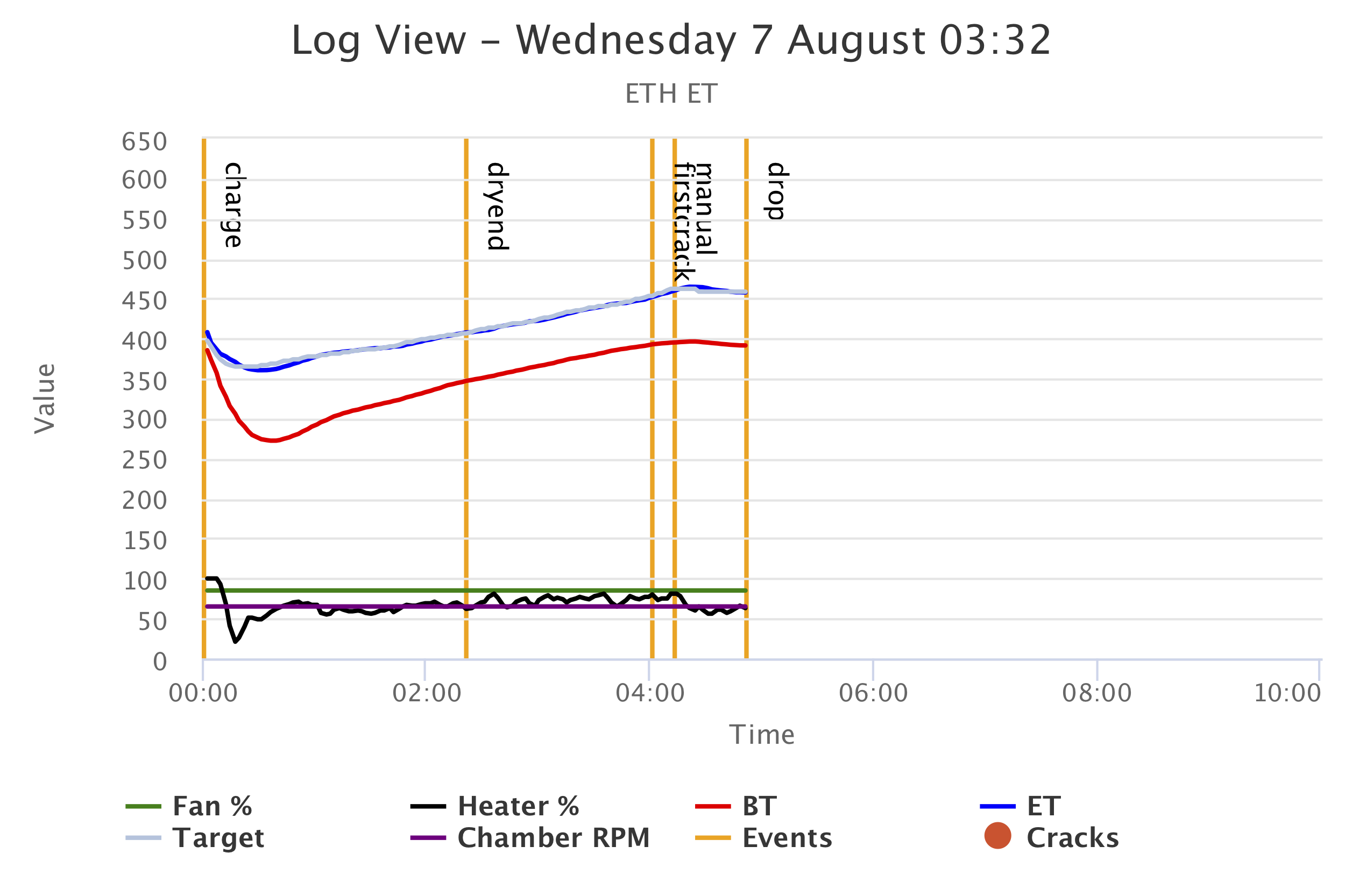

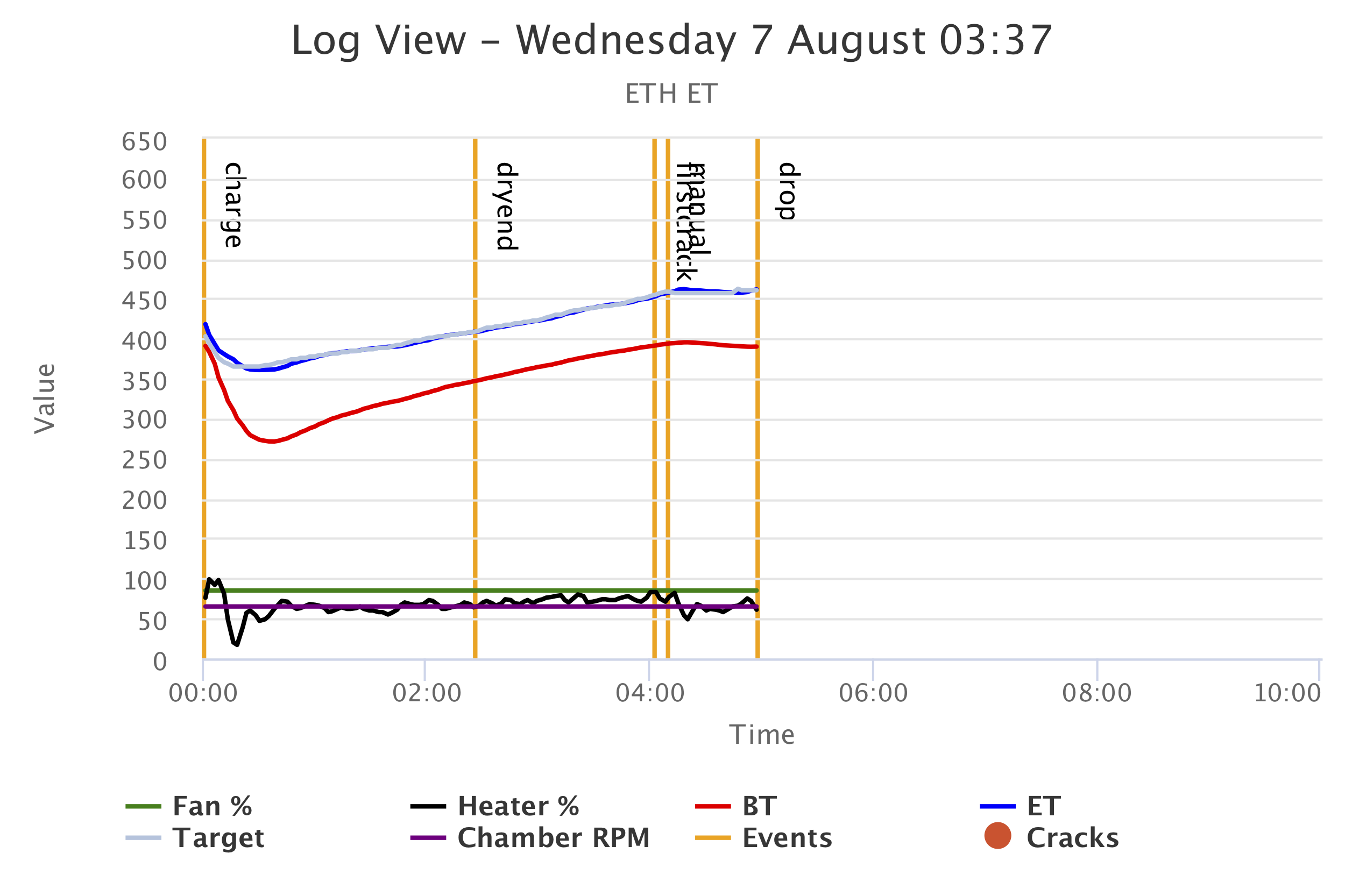

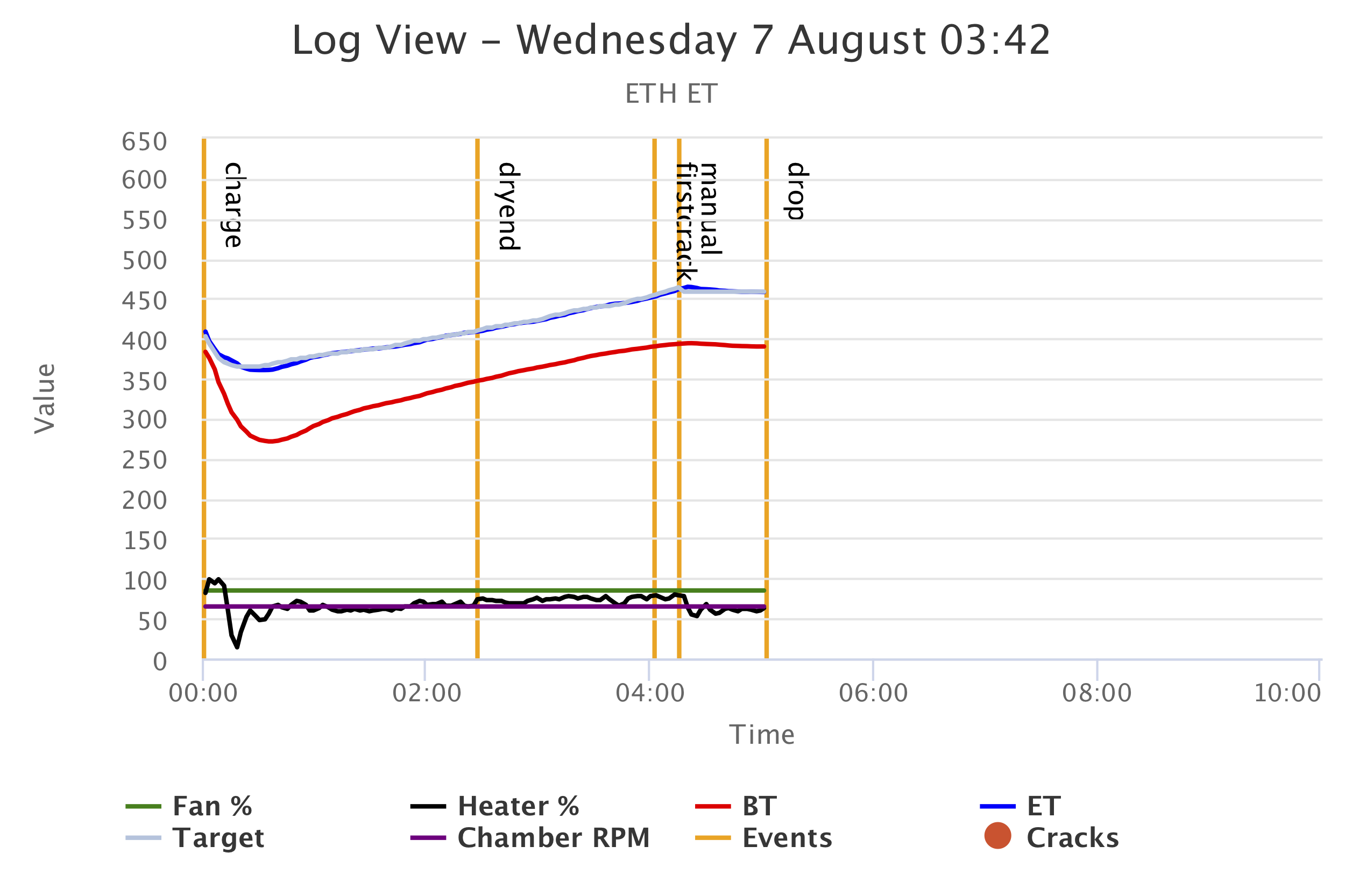

So – we ran a simple test. Take one coffee, six identical roasts prior to first crack, each of them having 5 additional seconds of development time. The development times ranged from :35 seconds all the way up to :60 seconds.

Going into the tasting, I think we both had a pre-conceived notion of how the results were going to play out. We chose to use a sample of Ethiopian coffee obtained from none other than the storied Heleanna Georgalis of Moplaco. The lot was Kasaye – Lot 14, a coffee from Shakiso that she had purchased through the ECX. We chose this for its outstanding clarity, complexity, and consistency. We knew that if there were any defects caused by roasting, they would certainly stand out. And oh boy – did they:

We were floored by the results. This started as a simple exercise, looking to see if our sweet spot had migrated from where it should be. To be honest, our roast times were right about where they should be. Like any roasts, hindsight is always 20/20 and nothing is perfect, but we were with :40 being our low-end of the spectrum and :45 being the high end. We were right in line. The astonishing part is how rapidly quality and cup score declined when roasts fell outside of those parameters.

- Cupping Notes

I can’t help but feel uneasy about what this could potentially mean for not only us, but for the coffee community in general – especially in countries where cup score is the sole determining factor for price paid. There’s no coincidence that all of our longest standing and most successful relationships with suppliers have remarkably talented Roasters working in their own respective Quality Control departments. But – as the saying goes, to err is human. No one is perfect, mistakes happen.

But, in a world where ten seconds of a roast can be the differentiator between an 87.5 point high end micro-lot, and an 84 point candidate for our RISE program, or a regional blend, we have a very small window in which to operate. Price paid for each of these prospects is vastly different. For me, this is a call to action.

At the very least, we need to readdress all roast profiles and make sure we’re doing everything we can to help the coffee to reach its full potential. Our livelihood as an organization may not rest on it, but the livelihood of so many other hardworking people does.

Written by Matt Hassell (Global buyer, QC & Sample Management)