May & June 2013 Cupping Events

Thank you to The Association and Prufrock Coffee for being such excellent hosts for our recent cupping events!

To recap: Our focus during the Association cupping were the Hacienda La Esmeralda Special auction lots. The Peterson family produces separate lots based on geographic areas, microclimates and picking dates from their farms and then auction these lots each year. The date for this year's auction is May 21st and we wanted to give UK roasters the opportunity to taste and form a buying group to bid on these amazing coffees during auction.

Our cupping at Prufrock had a broader focus and in addition to cupping the Esmeralda lots, cuppers tasted fresh crop Guatemalan and Honduran coffees coming from our friends at Bella Vista in Antigua and San Vincente in Santa Barbara. Also in the mix were soon-to-arrive Kenya and Ethiopia coffees.

There were great turnouts at these events! Thanks to all who took the time to join us.

May and June Events

For all you out there who couldn't join us in London, don't despair! We're make the rounds again in May and June. Mark your calendars!

Oslo: May 15 @ Kaffa Roastery. Esmeralda auction lots, Guatemala, Honduras, Kenya and Ethiopia.

Berlin: May 21 @ the Barn. Esmeralda auction lots. Auction is that day! May 28 @ the Barn: Guatemala, Honduras, Kenya and Ethiopia.

Nice: June 26-28 during SCAE World of Coffee. Details to follow!

London Again! April 23-24

London has become a second home for us at the Collaborative - especially at Prufrock Coffee, which has now welcomed and helped us co-host several cuppings since the very beginning. We have cupped some fantastic coffees and met some great coffee people within these walls, and now we are heading back to our London home again next week.

This time around, however, we have another venue and event to talk about: an exclusive cupping of coffees from Hacienda La Esmeralda at The Association. We have developed a great relationship over the years with the Peterson family, owners of Hacienda La Esmeralda. Throughout the history of Panama's Best of Panama competition, the Petersons and their geisha coffees have performed very well - winning or placing close to the top, many times. The quality and unique flavour characteristics have become so well regarded, that the family decided to hold their own auction, where lots are separated amongst their farms based on geographic areas and microclimates, and picking dates. These auction coffees comprise the Hacienda La Esmeralda Special lots.

Since 2006, we have been buying coffees from the Petersons and will offer their Esmeralda Boquete geisha blend this year, as we did last year. In addition to the Boquete Blend, we are excited to announce that we will be cupping this year's auction lots at The Association next week. This is an opportunity to be amongst the first to taste these amazing coffees, as well as provide interested roasters the opportunity to organize a buying group during the auction, which takes place on May 21st.

Where: The Association, 12 Creechurch Lane When: April 23, 4:30-6pm RSVP: Please confirm your attendance here

The next day, as part of UK Coffee Week, Prufrock is co-hosting a cupping where you will again have the opportunity to taste Esmeralda's auction lots. In addition, cuppers will taste fresh crop Guatemala and Honduran coffees from our friends at Bella Vista in Antigua and San Vincente in Santa Barbara. This is your chance to decide which lots are coming to Europe and into your roasteries before they are shipped! Also in the mix are soon-to-arrive Kenya coffees and again, you will have the opportunity to reserve the names you want offered in your menus.

See you there!

Photos: Antigua, Guatemala 2013

GUATEMALA Antigua, Buena Vista 2013, a set on Flickr.

Farm Profile: Pereira Sisters (formerly 'Fazenda Serrado')

Name: Pereira Sisters (formerly Fazenda Serrado) Total estate area (acre): 250 Altitude (masl): 1075-1229 Varietals: Bourbon, Acaiá, Mundo Novo, Catuaí and Catuaí

About

In 1971, Antonio Andrade Pereira Filho and Maria da Conceição Costa Pereira decided to invest in a farm of 90 acres in the city of Carmo de Minas, Minas Gerais. Antonio planted the first coffee seedlings and the couple started a family, raising two daughters: Maria and Maria Rogéria. Eventually the two women took over the running of the farm, along with their husbands, ushering in a new generation of coffee producers. With the eventual passing of Antonio, Maria and Maria Rogéria decided to continue running the farm together. Thus they changed the name of the farm from Serrado to Irmãs (Sisters) Pereira, ushering in a new spirit to their coffee production.

Irmas Pereira is perched in the high mountains of the South Minas Water Spa Circuit, near the towns of Lambari, Carmo de Minas and São Lourenço. The estate boasts great altitude, climate and dedicated management and workers. The coffee bushes grow in fertile mountain soil at altitudes ranging between 3,500 and 4,000 feet. These high altitudes favor slow ripening of cherries and permits selective picking; both decisive factors in producing exceptional coffees.

The estate utilizes top quality processing equipment: a state-of-the-art wet mill that recycles and reuses waste water, paved drying patios, mechanical driers and wooden silos for coffee to rest. However, the combination of these tools, combined with the exceptional climate and advanced agronomic techniques, would be wasted without the personal dedication of the estate’s owners and commitment the well-qualified team of approximately 35 employees.

New methods for Specialty coffees

With the new management, the family has invested in the production of specialty coffees and new processing methods.

Black honey parchment: Usually 100% of the mucilage is left, and during drying the cherries take on a distinctively dark color.

Double pass: Green (unripe) cherries are first separated from red and mature cherries in the washer. The mature cherries stay soaking in the tank for 12 hours and are then pulped.

Chuveirinho: After pulping, the coffee remains in a tank with cold water for more than 12 hours overnight and the next day they are sent to the drying area.

Unwashed Naturals: Green/unripe cherries are sorted out with the aid of a machine without any contact with water. Only mature cherries remain and these are then dried.

Honey: Between 50 – 100% of mucilage is left on the parchment. These cherries then become “red” or “black”, depending on the drying conditions.

Background to Carmo de Minas

Over the past decade, Brazil as a nation has experienced fantastic economic growth in every field, with higher purchasing power and an ever-increasing standard of living. At least 20 million people have risen above the poverty-line and the middle-class has grown by 40 million in a relatively few number of years. The value of labor has also increased: Brazil now has full employment and rising wages. All of this naturally affects the cost of coffee production in general, but it especially affects labor-intensive coffee (read: new processing methods with even higher costs). In some cases it is difficult to find labor at all, especially for farm work. Incentives must be strengthened in order to keep people at work within coffee. And as the world’s largest producer of coffee, Brazilian coffee is the main component of blends all over the world. Thus, the price paid for Brazilian coffee is a reflection of the fact that coffee from here is considered a base product. In parallel with fluctuations in world markets and in the pricing of coffee in general, the specialty coffee segment has established its own price dynamics.

Although coffee is an old commodity in Brazil, over the past 10-12 years, the country has been showcasing its very best coffee and it has only been in the last 7-8 years that coffee in the Carmo de Minas municipality has been particularly noteworthy.

Carmo is one village among twenty in the Mantiqueira region, south of the Minas Gerais county, in Sul de Minas. In the same way that Burgundy is an important name in the French world of wine, Carmo de Minas has become a destination in the Brazilian coffee world. Some of its distinction can be attributed to topographic and climatic conditions, but as always, there are people engaged – from picking coffee cherries to processing; both crucial to the quality of the product. People make the difference.

Although many of the farms in this area have won awards and garnered attention in recent years, there have not really been radical changes in farming and processing methods. Not even in terms of picking. We believe that the area has achieved its status with a little bit of luck, good growing conditions, good plant material – mostly Bourbon – but otherwise quite ordinary craft. However, good coffee has come out of all this and as a result, Carmo has experienced a “clean sweep” in Cup of Excellence competitions. But the quality can be even better, as well as the amount of the best coffee increased.

Jacques Pereira Carneiro represents the new generation in Carmo. Together with cousin Luis Paulo (who currently is president of Brazil Specialty Coffee Association (BSCA)), he runs the coffee export firm Carmo Coffees. These two men represent a 5th generation of coffee farmers and they collectively oversee 12 farms and 6 processing stations – altogether owned by their Pereira family. This family is also members of the cooperative Coca Rive, which offers its members courses on taste evaluation, distribution of fertilizer and storage facilities. Coca Rive has 400 members and is the smallest of the smallest cooperatives in the Carmo region, with its 8000 coffee farms. Previously Coca Rive worked almost exclusively with commercial coffee in this area and a few years ago it was a challenge to fill even one container (300 bags) of specialty coffee. Last year Carmo Coffees sold 150 containers of coffee over 80-points. We at CCS expect true specialty coffee from 86-points, but know that this proportion is also increasing in Carmo.

Carmo’s reputation is so well established that there is an ever-increasing demand for more coffee of their quality. Carmo Coffees does not just work with its own family’s production; it works hard to provide coffee from farms outside the family’s, including coffee from other districts. Pedralva, for example, is just a few miles from Carmo de Minas and many of the farms here are good, with altitudes up to 1400 meters above sea level. The work now is for a few farmers to push the idea of working a little differently to achieve better quality. With higher prices in the specialty coffee segment comes the motivation to do better than before. According to

Jacques, this change can be facilitated, but the first challenge is to pick a technique. On top of this are the added associated costs. Historically, the picking technique has been picking the coffee bush clean (stripping) during one picking and one harvesting season. Most people do this and even use partially mechanized equipment to do the job, which is more time-effective. But to get the sweetest coffee, you have to pick the sweetest, ripest cherries.

Minimum wage has increased to about $500 per month and although this is a low salary on any scale, these wages mean that the work of selective hand-picking coffee cherries represents up to 2/3 of the total cost of coffee production, even when coffee is sold at a 100% premium over commodity coffee.

Farm Profile: Fazenda Santa Inês

Name: Fazenda Santa Inês

Total estate area (acre): 530

Total area planted with coffee: 259

Varietals: Yellow Bourbon, Red Bourbon, Yellow Catuaí, Acaiá and Mundo Novo

Average Total Production (bags): 3 300

Average Pulped Natural Production: 1 500

Average Natural Production: 1 800

About

The Santa Inês estate is owned by the Sertão Group, a family firm with more than 100 years history in the production and commercialization of high-quality coffee. The Sertão Estate, located in Carmo de Minas, South Minas Gerais, was inherited by José Isidro Pereira and Nazareth Dias Pereira and is now managed by their sons and in-laws. The region is well known for its mineral water springs, perfect combination of latitude and altitude, mountainous terrain, well-defined seasons and fertile soil.

Favourable climatic and growing conditions found in South Minas have resulted in an expansion of the firm’s coffee program. The Sertão Group now possess large areas planted with coffee and are constantly developing infrastructure capable of producing a wide variety of high quality arabica coffee to both domestic and international markets.

In addition to coffee production the Sertão Group, in recent years, has successfully begun breeding and selling Girolando cattle, as well as cultivating and selling corn and soybeans. The firm employs highly qualified technical assistance in each of its areas of activity, in order to ensure the quality of the products.

The Sertão Group employs approximately 135 families that reside on-site throughout the year. These families make up the core of Sertão’s permanent team and are provided with free housing of good quality, running water, electricity, milk, coffee and fruit. In addition, on-site schools with fully qualified teachers for primary and secondary education, on-site medical and dental care, soccer fields and fishing ponds for leisure time, are provided.

In an effort to ensure and promote environmentally sustainable practice, programs have been implemented to preserve springs and water sources, wildlife, forests and other vegetation, and soil. All the water used in the washing tanks and pulpers is recycled, with residues transferred to settling ponds in order to avoid excessive use of water and contamination of the surrounding environment. The husks of pulped coffee, which are rich in nutrients, are used as fertilizer and organic matter in the coffee fields.

Background to Carmo de Minas

Over the past decade, Brazil as a nation has experienced fantastic economic growth in every field, with higher purchasing power and an ever-increasing standard of living. At least 20 million people have risen above the poverty-line and the middle-class has grown by 40 million in a relatively few number of years. The value of labor has also increased: Brazil now has full employment and rising wages. All of this naturally affects the cost of coffee production in general, but it especially affects labor-intensive coffee (read: new processing methods with even higher costs). In some cases it is difficult to find labor at all, especially for farm work. Incentives must be strengthened in order to keep people at work within coffee. And as the world’s largest producer of coffee, Brazilian coffee is the main component of blends all over the world. Thus, the price paid for Brazilian coffee is a reflection of the fact that coffee from here is considered a base product. In parallel with fluctuations in world markets and in the pricing of coffee in general, the specialty coffee segment has established its own price dynamics.

Although coffee is an old commodity in Brazil, over the past 10-12 years, the country has been showcasing its very best coffee and it has only been in the last 7-8 years that coffee in the Carmo de Minas municipality has been particularly noteworthy.

Carmo is one village among twenty in the Mantiqueira region, south of the Minas Gerais county, in Sul de Minas. In the same way that Burgundy is an important name in the French world of wine, Carmo de Minas has become a destination in the Brazilian coffee world. Some of its distinction can be attributed to topographic and climatic conditions, but as always, there are people engaged – from picking coffee cherries to processing; both crucial to the quality of the product. People make the difference.

Although many of the farms in this area have won awards and garnered attention in recent years, there have not really been radical changes in farming and processing methods. Not even in terms of picking. We believe that the area has achieved its status with a little bit of luck, good growing conditions, good plant material – mostly Bourbon – but otherwise quite ordinary craft. However, good coffee has come out of all this and as a result, Carmo has experienced a “clean sweep” in Cup of Excellence competitions. But the quality can be even better, as well as the amount of the best coffee increased.

Jacques Pereira Carneiro represents the new generation in Carmo. Together with cousin Luis Paulo (who currently is president of Brazil Specialty Coffee Association (BSCA)), he runs the coffee export firm Carmo Coffees. These two men represent a 5th generation of coffee farmers and they collectively oversee 12 farms and 6 processing stations – altogether owned by their Pereira family. This family is also members of the cooperative Coca Rive, which offers its members courses on taste evaluation, distribution of fertilizer and storage facilities. Coca Rive has 400 members and is the smallest of the smallest cooperatives in the Carmo region, with its 8000 coffee farms. Previously Coca Rive worked almost exclusively with commercial coffee in this area and a few years ago it was a challenge to fill even one container (300 bags) of specialty coffee. Last year Carmo Coffees sold 150 containers of coffee over 80-points. We at CCS expect true specialty coffee from 86-points, but know that this proportion is also increasing in Carmo.

Carmo’s reputation is so well established that there is an ever-increasing demand for more coffee of their quality. Carmo Coffees does not just work with its own family’s production; it works hard to provide coffee from farms outside the family’s, including coffee from other districts. Pedralva, for example, is just a few miles from Carmo de Minas and many of the farms here are good, with altitudes up to 1400 meters above sea level. The work now is for a few farmers to push the idea of working a little differently to achieve better quality. With higher prices in the specialty coffee segment comes the motivation to do better than before. According to Jacques, this change can be facilitated, but the first challenge is to pick a technique. On top of this are the added associated costs. Historically, the picking technique has been picking the coffee bush clean (stripping) during one picking and one harvesting season. Most people do this and even use partially mechanized equipment to do the job, which is more time-effective. But to get the sweetest coffee, you have to pick the sweetest, ripest cherries.

Minimum wage has increased to about $500 per month and although this is a low salary on any scale, these wages mean that the work of selective hand-picking coffee cherries represents up to 2/3 of the total cost of coffee production, even when coffee is sold at a 100% premium over commodity coffee.

Farm Profile: Fazenda Santa Lúcia

Name: Fazenda Santa Lúcia

Total estate area (acre): 1 828

Total area planted with coffee: 205

Varietals: Yellow Bourbon, Catuaí, Acaiá and Mundo Novo

Average Total Production (bags): 2 800

Average Pulped Natural Production: 1 260

Average Natural Production: 1 540

Name: Fazenda Santa Lúcia

Total estate area (acre): 1 828

Total area planted with coffee: 205

Varietals: Yellow Bourbon, Catuaí, Acaiá and Mundo Novo

Average Total Production (bags): 2 800

Average Pulped Natural Production: 1 260

Average Natural Production: 1 540

About The Santa Lucia estate is owned by the Sertão Group, a family firm with more than 100 years history in the production and commercialization of high-quality coffee. The Sertão Estate, located in Carmo de Minas, South Minas Gerais, was inherited by José Isidro Pereira and Nazareth Dias Pereira and is now managed by their sons and in-laws. The region is well known for its mineral water springs, perfect combination of latitude and altitude, mountainous terrain, well-defined seasons and fertile soil.

Favourable climatic and growing conditions found in South Minas have resulted in an expansion of the firm’s coffee program. The Sertão Group now possess large areas planted with coffee and are constantly developing infrastructure capable of producing a wide variety of high quality arabica coffee to both domestic and international markets.

In addition to coffee production the Sertão Group, in recent years, has successfully begun breeding and selling Girolando cattle, as well as cultivating and selling corn and soybeans. The firm employs highly qualified technical assistance in each of its areas of activity, in order to ensure the quality of the products.

The Sertão Group employs approximately 135 families that reside on-site throughout the year. These families make up the core of Sertão’s permanent team and are provided with free housing of good quality, running water, electricity, milk, coffee and fruit. In addition, on-site schools with fully qualified teachers for primary and secondary education, on-site medical and dental care, soccer fields and fishing ponds for leisure time, are provided.

In an effort to ensure and promote environmentally sustainable practice, programs have been implemented to preserve springs and water sources, wildlife, forests and other vegetation, and soil. All the water used in the washing tanks and pulpers is recycled, with residues transferred to settling ponds in order to avoid excessive use of water and contamination of the surrounding environment. The husks of pulped coffee, which are rich in nutrients, are used as fertilizer and organic matter in the coffee fields.

Background to Carmo de Minas

Over the past decade, Brazil as a nation has experienced fantastic economic growth in every field, with higher purchasing power and an ever-increasing standard of living. At least 20 million people have risen above the poverty-line and the middle-class has grown by 40 million in a relatively few number of years. The value of labor has also increased: Brazil now has full employment and rising wages. All of this naturally affects the cost of coffee production in general, but it especially affects labor-intensive coffee (read: new processing methods with even higher costs). In some cases it is difficult to find labor at all, especially for farm work. Incentives must be strengthened in order to keep people at work within coffee. And as the world’s largest producer of coffee, Brazilian coffee is the main component of blends all over the world. Thus, the price paid for Brazilian coffee is a reflection of the fact that coffee from here is considered a base product. In parallel with fluctuations in world markets and in the pricing of coffee in general, the specialty coffee segment has established its own price dynamics.

Although coffee is an old commodity in Brazil, over the past 10-12 years, the country has been showcasing its very best coffee and it has only been in the last 7-8 years that coffee in the Carmo de Minas municipality has been particularly noteworthy.

Carmo is one village among twenty in the Mantiqueira region, south of the Minas Gerais county, in Sul de Minas. In the same way that Burgundy is an important name in the French world of wine, Carmo de Minas has become a destination in the Brazilian coffee world. Some of its distinction can be attributed to topographic and climatic conditions, but as always, there are people engaged – from picking coffee cherries to processing; both crucial to the quality of the product. People make the difference.

Although many of the farms in this area have won awards and garnered attention in recent years, there have not really been radical changes in farming and processing methods. Not even in terms of picking. We believe that the area has achieved its status with a little bit of luck, good growing conditions, good plant material – mostly Bourbon – but otherwise quite ordinary craft. However, good coffee has come out of all this and as a result, Carmo has experienced a “clean sweep” in Cup of Excellence competitions. But the quality can be even better, as well as the amount of the best coffee increased.

Jacques Pereira Carneiro represents the new generation in Carmo. Together with cousin Luis Paulo (who currently is president of Brazil Specialty Coffee Association (BSCA)), he runs the coffee export firm Carmo Coffees. These two men represent a 5th generation of coffee farmers and they collectively oversee 12 farms and 6 processing stations – altogether owned by their Pereira family. This family is also members of the cooperative Coca Rive, which offers its members courses on taste evaluation, distribution of fertilizer and storage facilities. Coca Rive has 400 members and is the smallest of the smallest cooperatives in the Carmo region, with its 8000 coffee farms. Previously Coca Rive worked almost exclusively with commercial coffee in this area and a few years ago it was a challenge to fill even one container (300 bags) of specialty coffee. Last year Carmo Coffees sold 150 containers of coffee over 80-points. We at CCS expect true specialty coffee from 86-points, but know that this proportion is also increasing in Carmo.

Carmo’s reputation is so well established that there is an ever-increasing demand for more coffee of their quality. Carmo Coffees does not just work with its own family’s production; it works hard to provide coffee from farms outside the family’s, including coffee from other districts. Pedralva, for example, is just a few miles from Carmo de Minas and many of the farms here are good, with altitudes up to 1400 meters above sea level. The work now is for a few farmers to push the idea of working a little differently to achieve better quality. With higher prices in the specialty coffee segment comes the motivation to do better than before. According to Jacques, this change can be facilitated, but the first challenge is to pick a technique. On top of this are the added associated costs. Historically, the picking technique has been picking the coffee bush clean (stripping) during one picking and one harvesting season. Most people do this and even use partially mechanized equipment to do the job, which is more time-effective. But to get the sweetest coffee, you have to pick the sweetest, ripest cherries.

Minimum wage has increased to about $500 per month and although this is a low salary on any scale, these wages mean that the work of selective hand-picking coffee cherries represents up to 2/3 of the total cost of coffee production, even when coffee is sold at a 100% premium over commodity coffee.

Update from Nairobi, Kenya - February 2013

We have known for a while that the 2013 harvest would be a little later than last year; the crop smaller. As a result, we have been expecting improved quality from last year: more intensity in flavor and better processing. And this is exactly what we have found!

We have known for a while that the 2013 harvest would be a little later than last year; the crop smaller. As a result, we have been expecting improved quality from last year: more intensity in flavor and better processing. And this is exactly what we have found!

Timing is key The cooperatives have held onto their coffees until recently, waiting until the market went up. In the Nyeri region, the cooperatives we usually like best, have kept their coffee at their warehouses to rest, but have also "timed" when to present them to the Kenya Coffee Auction in Nairobi, where they are trying to fetch as high a price as possible. We don't blame them for this. That said, one of the reasons we were there now is to buy the best coffees before they are presented to the auction at all. These days, the very best coffees aren’t usually sold at auction; they are being sold right off the cupping table! Thus, we need to be present at origin, tasting all the coffees and informing the coops what we want before anybody else does. The competition for the best lots is fierce. And fun.

Perfect timing is best We could have been in Kenya two weeks ago and we would have gotten first choice on some lots. At the time, however, there was much less variety in the coffees being offered. We could have waited until after the elections in March to go: a time when most coffees are made available. But this is too late - the best lots would have been sold in the meantime.

We want to get first pick of the best lots, but we also want to choose from as many lots as possible, which is why last week proved to be perfect timing for choosing the best lots from the 2013 harvest.

Mission completed It should go without saying that we always cup blind. Still, we usually end up choosing lots from the same cooperatives we have liked in the past. Frankly, these consistent favorites are now famous and internationally recognized for producing the best Kenyan coffees, fetching the best prices and in turn, paying the best prices to farmer-members. Overall, this is a win-win situation we like being a part of.

Generally speaking, the lots chosen have a powerful aroma with the characteristic berry notes one can expect from a great Nyeri coffee. Below are the names of the coops we have selected from:

the Good Old names:

from Tekangu Coop in Karatina, Nyeri

- TEGU - KARAGOTO

- NGUNGURU

- KARAGOTO

- NGUNGURU

from Barichu Coop in Karatina, Nyeri - GATOMBOYA

from Gikanda Coop in Karatina, Nyeri - KANGOCHO

from Mugaga Coop in Karatina, Nyeri - KIENI - KAGUMOINI

the Good New names:

from Aguthi Coop in Nyeri, Nyeri - KAGUMO

from Mugaga Coop in Karatina, Nyeri - GATINA

from Gakuyu Coop in Karatina, Nyeri - NDIMAINI

from Barichu Coop in Karatina, Nyeri - GATURIRI

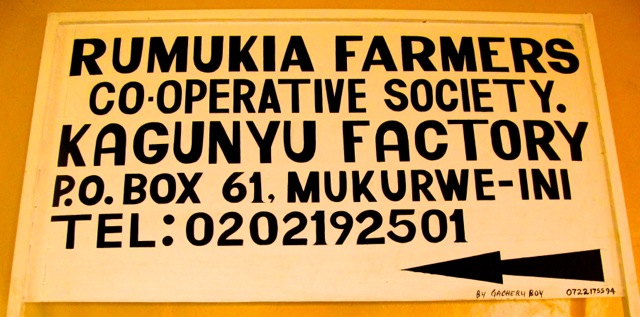

from Rumukia Coop in Mukurwe, Nyeri - KIAWAMURURU

- KIAWAMURURU

from Karithathi Coop in Kianyaga, Kirinyaga - KIUNYU

On Screening and Quality Selection Size matters, but not always in the way one would think.

In Kenya, a coffee "lot" is made from a bigger batch of coffee that is delivered to the dry-mill from a cooperative on a given day. When a coffee batch arrives at the mill, it is processed (hulled), analyzed (technically and sensorially), screened (separated due to bean sizes) and given an outturn-number. While the parchment is taken off the beans in the hulling process, the beans are screened and separated due to shape and size.

AAs are flat with screen size 17+. ABs are flat with screen sizes 15&16. PBs are pea-berries. There are always a certain percentage of lower grades too.

For example: the whole truckload of coffee from Gatomboya’s warehouse that arrived at the mill in Karatina last week was given the outturn-number 20CK0032. Let’s say this outturn is 30% AA, 55% AB, 5% PB and 10% lower grades. These qualities are of course kept, tasted and sold (or auctioned) separately.

In actual fact, we are getting Gatomboya 20CK0032 in AA, AB and PB because we think there is an interesting and consistent good linkage amongst the various screen sizes.

Screen size does not necessarily correlate with quality in terms of flavor attributes! For example, last year we found many of the AB-selections to be superior to the AAs from the same lot. It is NOT true that PBs are necessarily more intense in flavor or better in quality than the flat beans.

The only truth is that EVERY lot and ALL qualities must be evaluated. Separately. As Always, Cupping is Key.

That said, we do see some patterns. This year we have found many of the AAs to be superior - by far. (Thus they come with a much higher premium.) Still, all the qualities we have chosen are the best in their respective category. All the AAs this year are stellar!

Contact us to order

Ethiopia Trip, November 2012 (video)

https://vimeo.com/channels/417597/57598150 Robert and Joanna visit a farm delivering to the Konga Farmers Cooperative in Yirgacheffe, Ethiopia Link to Full Post...

https://vimeo.com/57599687

Interview with Bashir (Pt. I) Link to Full Post...

https://vimeo.com/57849882

Interview with Bashir (Pt. II) Link to Full Post...

https://vimeo.com/57850353

Interview with Bashir (Pt. III) Link to Full Post...

https://vimeo.com/57851833

Chat with the Konga cooperative's wetmill manager Link to Full Post...

https://vimeo.com/57853951

A Konga cherry producer delivers cherry and describes coffee picking and the process of how cherry is weighed and purchased by the wetmill Link to Full Post...

https://vimeo.com/57855362

Konga coffee processing: washing/demucilage Link to Full Post...

Farm Profile: Fazenda São Benedito

Name: Fazenda São Benedito

Producer: Hélcio Jr.

Total estate area (acre): 578

Total area planted with coffee: 126

Varietals: Yellow Bourbon, Catuaí, Mundo Novo, with Yellow and Red Bourbon planned for future planting

Average Total Production (bags): 1 800

Average Pulped Natural Production: 800

Average Natural Production: 1 000

Name: Fazenda São Benedito

Producer: Hélcio Jr.

Total estate area (acre): 578

Total area planted with coffee: 126

Varietals: Yellow Bourbon, Catuaí, Mundo Novo, with Yellow and Red Bourbon planned for future planting

Average Total Production (bags): 1 800

Average Pulped Natural Production: 800

Average Natural Production: 1 000

About

The São Benedito estate is owned by Hélcio Jr. and the Sertão Group, a family firm with more than 100 years history in the production and commercialization of high-quality coffee. The region is well known for its mineral water springs, perfect combination of latitude and altitude, mountainous terrain, well defined seasons and fertile soil.

Favourable climatic and growing conditions found in South Minas have resulted in an expansion of the firm’s coffee program. The Sertão Group now possess large areas planted with coffee and are constantly developing infrastructure capable of producing a wide variety of high quality arabica coffee to both domestic and international markets.

In addition to coffee production the Sertão Group, in recent years, has successfully begun breeding and selling Girolando cattle, as well as cultivating and selling corn and soybeans. The firm employs highly qualified technical assistance in each of its areas of activity, in order to ensure the quality of the products.

The Sertão Group employs approximately 135 families that reside on-site throughout the year. These families make up the core of Sertão’s permanent team and are provided with free housing of good quality, running water, electricity, milk, coffee and fruit. In addition, on-site schools with fully qualified teachers for primary and secondary education, on-site medical and dental care, soccer fields and fishing ponds for leisure time, are provided.

In an effort to ensure and promote environmentally sustainable practice, programs have been implemented to preserve springs and water sources, wildlife, forests and other vegetation, and soil. All the water used in the washing tanks and pulpers is recycled, with residues transferred to settling ponds in order to avoid excessive use of water and contamination of the surrounding environment. The husks of pulped coffee, which are rich in nutrients, are used as fertilizer and organic matter in the coffee fields.

During the 2005 Cup of Excellence competition, São Benedito won second place with a score of 92.65 points.

Background to Carmo de Minas

Over the past decade, Brazil as a nation has experienced fantastic economic growth in every field, with higher purchasing power and an ever-increasing standard of living. At least 20 million people have risen above the poverty-line and the middle-class has grown by 40 million in a relatively few number of years. The value of labor has also increased: Brazil now has full employment and rising wages. All of this naturally affects the cost of coffee production in general, but it especially affects labor-intensive coffee (read: new processing methods with even higher costs). In some cases it is difficult to find labor at all, especially for farm work. Incentives must be strengthened in order to keep people at work within coffee. And as the world’s largest producer of coffee, Brazilian coffee is the main component of blends all over the world. Thus, the price paid for Brazilian coffee is a reflection of the fact that coffee from here is considered a base product. In parallel with fluctuations in world markets and in the pricing of coffee in general, the specialty coffee segment has established its own price dynamics.

Although coffee is an old commodity in Brazil, over the past 10-12 years, the country has been showcasing its very best coffee and it has only been in the last 7-8 years that coffee in the Carmo de Minas municipality has been particularly noteworthy.

Carmo is one village among twenty in the Mantiqueira region, south of the Minas Gerais county, in Sul de Minas. In the same way that Burgundy is an important name in the French world of wine, Carmo de Minas has become a destination in the Brazilian coffee world. Some of its distinction can be attributed to topographic and climatic conditions, but as always, there are people engaged – from picking coffee cherries to processing; both crucial to the quality of the product. People make the difference.

Although many of the farms in this area have won awards and garnered attention in recent years, there have not really been radical changes in farming and processing methods. Not even in terms of picking. We believe that the area has achieved its status with a little bit of luck, good growing conditions, good plant material – mostly Bourbon – but otherwise quite ordinary craft. However, good coffee has come out of all this and as a result, Carmo has experienced a “clean sweep” in Cup of Excellence competitions. But the quality can be even better, as well as the amount of the best coffee increased.

Jacques Pereira Carneiro represents the new generation in Carmo. Together with cousin Luis Paulo (who currently is president of Brazil Specialty Coffee Association (BSCA)), he runs the coffee export firm Carmo Coffees. These two men represent a 5th generation of coffee farmers and they collectively oversee 12 farms and 6 processing stations – altogether owned by their Pereira family. This family is also members of the cooperative Coca Rive, which offers its members courses on taste evaluation, distribution of fertilizer and storage facilities. Coca Rive has 400 members and is the smallest of the smallest cooperatives in the Carmo region, with its 8000 coffee farms. Previously Coca Rive worked almost exclusively with commercial coffee in this area and a few years ago it was a challenge to fill even one container (300 bags) of specialty coffee. Last year Carmo Coffees sold 150 containers of coffee over 80-points. We at CCS expect true specialty coffee from 86-points, but know that this proportion is also increasing in Carmo.

Carmo’s reputation is so well established that there is an ever-increasing demand for more coffee of their quality. Carmo Coffees does not just work with its own family’s production; it works hard to provide coffee from farms outside the family’s, including coffee from other districts. Pedralva, for example, is just a few miles from Carmo de Minas and many of the farms here are good, with altitudes up to 1400 meters above sea level. The work now is for a few farmers to push the idea of working a little differently to achieve better quality. With higher prices in the specialty coffee segment comes the motivation to do better than before. According to Jacques, this change can be facilitated, but the first challenge is to pick a technique. On top of this are the added associated costs. Historically, the picking technique has been picking the coffee bush clean (stripping) during one picking and one harvesting season. Most people do this and even use partially mechanized equipment to do the job, which is more time-effective. But to get the sweetest coffee, you have to pick the sweetest, ripest cherries.

Minimum wage has increased to about $500 per month and although this is a low salary on any scale, these wages mean that the work of selective hand-picking coffee cherries represents up to 2/3 of the total cost of coffee production, even when coffee is sold at a 100% premium over commodity coffee.

Farm Profile: Fazenda Sertão

Name: Fazenda Sertão

Total estate area (acre): 1 976

Total area planted with coffee: 519

Varietals: Yellow Bourbon, Red Bourbon, Yellow Catuaí, Acaiá, Mundo Novo, Icatu and Catucaí

Average Total Production (bags): 6 200

Average Pulped Natural Production: 2 800

Average Natural Production: 3 400

Name: Fazenda Sertão

Total estate area (acre): 1 976

Total area planted with coffee: 519

Varietals: Yellow Bourbon, Red Bourbon, Yellow Catuaí, Acaiá, Mundo Novo, Icatu and Catucaí

Average Total Production (bags): 6 200

Average Pulped Natural Production: 2 800

Average Natural Production: 3 400

About

The Sertão estate is owned by the Sertão Group, a family firm with more than 100 years history in the production and commercialization of high-quality coffee. The Sertão Estate, located in Carmo de Minas, South Minas Gerais, was inherited by José Isidro Pereira and Nazareth Dias Pereira and is now managed by their sons and in-laws. The region is well known for its mineral water springs, perfect combination of latitude and altitude, mountainous terrain, well-defined seasons and fertile soil.

Favourable climatic and growing conditions found in South Minas have resulted in an expansion of the firm’s coffee program. The Sertão Group now possess large areas planted with coffee and are constantly developing infrastructure capable of producing a wide variety of high quality arabica coffee to both domestic and international markets.

In addition to coffee production the Sertão Group, in recent years, has successfully begun breeding and selling Girolando cattle, as well as cultivating and selling corn and soybeans. The firm employs highly qualified technical assistance in each of its areas of activity, in order to ensure the quality of the products.

The Sertão Group employs approximately 135 families that reside on-site throughout the year. These families make up the core of Sertão’s permanent team and are provided with free housing of good quality, running water, electricity, milk, coffee and fruit. In addition, on-site schools with fully qualified teachers for primary and secondary education, on-site medical and dental care, soccer fields and fishing ponds for leisure time, are provided.

In an effort to ensure and promote environmentally sustainable practice, programs have been implemented to preserve springs and water sources, wildlife, forests and other vegetation, and soil. All the water used in the washing tanks and pulpers is recycled, with residues transferred to settling ponds in order to avoid excessive use of water and contamination of the surrounding environment. The husks of pulped coffee, which are rich in nutrients, are used as fertilizer and organic matter in the coffee fields.

Background to Carmo de Minas

Over the past decade, Brazil as a nation has experienced fantastic economic growth in every field, with higher purchasing power and an ever-increasing standard of living. At least 20 million people have risen above the poverty-line and the middle-class has grown by 40 million in a relatively few number of years. The value of labor has also increased: Brazil now has full employment and rising wages. All of this naturally affects the cost of coffee production in general, but it especially affects labor-intensive coffee (read: new processing methods with even higher costs). In some cases it is difficult to find labor at all, especially for farm work. Incentives must be strengthened in order to keep people at work within coffee. And as the world’s largest producer of coffee, Brazilian coffee is the main component of blends all over the world. Thus, the price paid for Brazilian coffee is a reflection of the fact that coffee from here is considered a base product. In parallel with fluctuations in world markets and in the pricing of coffee in general, the specialty coffee segment has established its own price dynamics.

Although coffee is an old commodity in Brazil, over the past 10-12 years, the country has been showcasing its very best coffee and it has only been in the last 7-8 years that coffee in the Carmo de Minas municipality has been particularly noteworthy.

Carmo is one village among twenty in the Mantiqueira region, south of the Minas Gerais county, in Sul de Minas. In the same way that Burgundy is an important name in the French world of wine, Carmo de Minas has become a destination in the Brazilian coffee world. Some of its distinction can be attributed to topographic and climatic conditions, but as always, there are people engaged – from picking coffee cherries to processing; both crucial to the quality of the product. People make the difference.

Although many of the farms in this area have won awards and garnered attention in recent years, there have not really been radical changes in farming and processing methods. Not even in terms of picking. We believe that the area has achieved its status with a little bit of luck, good growing conditions, good plant material – mostly Bourbon – but otherwise quite ordinary craft. However, good coffee has come out of all this and as a result, Carmo has experienced a “clean sweep” in Cup of Excellence competitions. But the quality can be even better, as well as the amount of the best coffee increased.

Jacques Pereira Carneiro represents the new generation in Carmo. Together with cousin Luis Paulo (who currently is president of Brazil Specialty Coffee Association (BSCA)), he runs the coffee export firm Carmo Coffees. These two men represent a 5th generation of coffee farmers and they collectively oversee 12 farms and 6 processing stations – altogether owned by their Pereira family. This family is also members of the cooperative Coca Rive, which offers its members courses on taste evaluation, distribution of fertilizer and storage facilities. Coca Rive has 400 members and is the smallest of the smallest cooperatives in the Carmo region, with its 8000 coffee farms. Previously Coca Rive worked almost exclusively with commercial coffee in this area and a few years ago it was a challenge to fill even one container (300 bags) of specialty coffee. Last year Carmo Coffees sold 150 containers of coffee over 80-points. We at CCS expect true specialty coffee from 86-points, but know that this proportion is also increasing in Carmo.

Carmo’s reputation is so well established that there is an ever-increasing demand for more coffee of their quality. Carmo Coffees does not just work with its own family’s production; it works hard to provide coffee from farms outside the family’s, including coffee from other districts. Pedralva, for example, is just a few miles from Carmo de Minas and many of the farms here are good, with altitudes up to 1400 meters above sea level. The work now is for a few farmers to push the idea of working a little differently to achieve better quality. With higher prices in the specialty coffee segment comes the motivation to do better than before. According to Jacques, this change can be facilitated, but the first challenge is to pick a technique. On top of this are the added associated costs. Historically, the picking technique has been picking the coffee bush clean (stripping) during one picking and one harvesting season. Most people do this and even use partially mechanized equipment to do the job, which is more time-effective. But to get the sweetest coffee, you have to pick the sweetest, ripest cherries.

Minimum wage has increased to about $500 per month and although this is a low salary on any scale, these wages mean that the work of selective hand-picking coffee cherries represents up to 2/3 of the total cost of coffee production, even when coffee is sold at a 100% premium over commodity coffee.

Washing Station Profile: Masha

Name: Masha

Operator: Greenco

Province: Kayanza

Commune: Gatare

Construction Date: 1989

Processing capacity (mt): >750

Elevation (masl): 1 672

Variety: Red Bourbon

Soil: Hygro-Xéro-Ferralsols with Ferralic

Number of delivering cherry producers: 467

Average trees per farmer: 387

Processing method: Fully washed

Name: Masha

Operator: Greenco

Province: Kayanza

Commune: Gatare

Construction Date: 1989

Processing capacity (mt): >750

Elevation (masl): 1 672

Variety: Red Bourbon

Soil: Hygro-Xéro-Ferralsols with Ferralic

Number of delivering cherry producers: 467

Average trees per farmer: 387

Processing method: Fully washed

About Masha

In 2012 Masha coffee washing station (CWS) placed amongst the winning lots in Burundi’s inaugural Cup of Excellence. The station has won 8 prizes at the Cup Of Excellence since that inaugural year. Excellent soil conditions, good altitudes, ripe cherry selection from delivering producers and a good water source are amongst the many reasons Masha’s manager believes the washing station is producing some of Burundi’s best coffee.

In the cup, the coffee consistently exhibits a well-balanced profile with tangerine-like acidity and sweetness backed by a honey sweetness that lingers in after taste.

Background to Greenco

Greenco is a subsidiary of BCC (Bercher Coffee Consulting), a Geneva based company established by François Bercher a few years ago.

Mr. Bercher is passionate about Burundi and its coffee and has gained extensive knowledge about, as well as has forged tight links with many key people working throughout the coffee sector, through his many years working as a coffee trader within the country. Since recently settling in Switzerland and starting his own company, François has continued to regularly source coffee from Burundi. In order to source consistently good coffee, he decided to invest his time and resources in being closer to field (e.g. through managing washing stations). In this way, he is able to have more control and influence over his coffees’ quality. This is especially crucial within an infant specialty coffee market such as Burundi’s.

Formerly being a regular buyer of coffee from Webcor (former management company and owner of Yandaro CWS) and thus knowing Webcor's operations very well, François decided to enter into a partnership with them. He knew from past experience that Webcor had purchased and run some of the best CWSs in Burundi, in part by being the first private company to buy CWSes during the country’s first stage of privatization of its coffee sector. It is therefore not surprising that with François' knowledge of Burundian coffee, his working with the best CWSes in the country, along with his high ambitions, that Greenco has had a very successful first year.

Burundi Coffee: Background context

Burundi is a landlocked country in Central Africa bordered by the Democratic Republic of the Congo, Rwanda and Tanzania. The official languages are Kirundi and French, with pockets of Swahili being spoken mostly in Bujumbura (the capital city), along Lake Tanganyika. Hilly and mountainous, Burundi boasts ideal agroecology for coffee cultivation. The country’s economy is predominantly agricultural with more than 90% of the population dependent on subsistence agriculture. Economic growth depends very heavily on coffee and tea exports, which together account for 90% of foreign exchange earnings.

Coffee growing and production began during Belgian occupation in the early 1930s and from 1980 to 1993, Burundi invested heavily in the coffee subsector with the heavy assistance—both monetary and strategic—of the World Bank, which helped implement an ambitious program of coffee washing station construction and tree planting. During these years, the number of coffee shrubs increased from 90 million to over 220 million and 133 washing stations were built and strategically placed throughout the country. Currently, there are over 160 washing stations in Burundi.

Coffee is Burundi’s biggest export revenue earner, making up as high as 80% of earnings. There are 600 000 families, close to 40% of the population, involved in the coffee subsector. Until 2007, the coffee subsector was controlled by the state, with the result that all facilities (i.e. washing stations and dry mills) and exporting were coordinated by the government. Coffee has historically been of low quality, subsequently receiving low prices dependent on commodities exchange markets. However, in 2006, the government started liberalizing the subsector and began allowing privatization of coffee washing stations (CWS) and dry mills leading to a continuing expansion of producer access into high quality specialty markets.

The hilly topography of Burundi has made for how the country is organized politically and infrastructurally. A colline in Burundi (i.e. hill) is like a borough or rural neighbourhood. Ultimately, a certain number of collines constitute a commune (i.e. county). The farmers that live on one colline are likely to deliver their coffee cherries to the same washing station that is located within accessible distance from their farms. The different lots represent day-lots from these wet mills.

The climate in Burundi is predominantly equatorial, but the many hilly and mountainous regions, where coffee is grown, enjoy a moderate climate. Average temperatures vary from 17 to 23C and there are distinct wet and dry seasons: the dry seasons run from June to August and again from December to January; the wet seasons are February to May and September to November. These factors, combined with the country’s agroecology, combine for an ideal environment for coffee growing. Under these conditions, cherries can undergo ideal development due to stable and the relatively low temperatures on the plains. In addition, the distinct seasons allow for a proper blossoming of the plants and good drying conditions for the coffee beans (seeds). The main flowering period runs from October until November and there are two harvesting periods: the main harvest runs from February to March; the secondary harvest from April until May.

Part II: The Transition Toward Quality

In Part I, a brief introduction to some major contributors to Burundi’s coffee subsector was made. I focused on three main groups currently involved in the processing and distributing of coffee once the cherries have been picked: the SOGESTAL (now, increasingly privately owned coffee washing stations (CWS)), local buyers (washing stations, amongst others) and dry mills.

In Part I, a brief introduction to some major contributors to Burundi’s coffee subsector was made. I focused on three main groups currently involved in the processing and distributing of coffee once the cherries have been picked: the SOGESTAL (now, increasingly privately owned coffee washing stations (CWS)), local buyers (washing stations, amongst others) and dry mills.

This post will focus on how Burundi has begun moving from a coffee market selling low-quality commodities coffee into one that produces high quality specialty coffee. It is a significant shift in Burundi’s coffee paradigm and its success will require long-term planning, investment and the collective action and will of everyone involved. In this post, I wrote about USAID’s involvement in the process and how Burundi’s government has started to liberalize coffee through the privatization of CWSes and dry mills.

[gigya src="http://www.flickr.com/apps/slideshow/show.swf?v=71649" width="700" flashvars="offsite=true&lang=en-us&page_show_url=/photos/kaffa1/sets/72157631279228920/show/&page_show_back_url=/photos/kaffa1/sets/72157631279228920/&set_id=72157631279228920&jump_to=" allowFullScreen="true" ]

The Transition

From my readings and the conversations I had with people throughout Burundi’s coffee sector, I learned that the already long and complex liberalization process would be even slower going without the involvement of USAID. As an example: when the first tender went out for washing stations, the government wanted cherry producers (via farmers' groups/associations/cooperatives) to acquire part ownership. In such a scenario, both buyers and sellers would have control of the processing capacity – a clear conflict of interest. One of the obvious questions outlined by potential buyers was: who are these people we’re supposed to be sharing ownership with? If partners with competing interests own the same washing station, whose interests win out? Is it the farmers (sellers who want to sell high) or private companies (potentially exporters wanting to buy low)? There was no precedent for this type of model; no other set of experiences to help make sense of how this was all supposed to work. In fact, farmers’ associations/cooperatives have not been able to organize themselves in order to buy the government suggested share of the washing stations (approx. 25%) and the government still own shares in washing stations that have been purchased privately.

With USAID’s involvement, companies that decided to go ahead and purchase CWSes had support and a bit of an intermediary to help smooth the transition from a government controlled industry to a semi-privatized one (the government still retains control of varying shares of each washing station). Cherry producers have been quite skeptical of companies buying up washing stations. A big part of the problem was mis-communication on the government’s part with respect to CWS ownership. Instead of communicating that producers were paying taxes to maintain CWSes, the government characterized them as payments that would eventually lead to coffee farmers groups’ ownership.

Also problematic is that governments, generally, aren’t very good at running things tightly and efficiently. The case of Burundi’s SOGESTALs is no exception. These have a history of running with huge overhead costs and producers have never been given the opportunity to participate in anything other than cherry production. They had no involvement or knowledge about markets and pricing; they constantly were or felt like they were being cheated (e.g. paid for less cherries than they delivered); they had no access to advances in agricultural knowledge and technology and no access to international buyers with whom they could negotiate. Amongst many, two consequences were low quality coffee and wildly fluctuating production levels.

What’s Been Done?

USAID’s five-year program (Burundi Agribusiness Program), which ended in November 2012, was significant in Burundi’s move toward high quality coffee production. The program, while small in scope in its targeting of a small number of washing stations and regions, seems to have provided the necessary initial push toward better agricultural practice, a marketing strategy (almost nonexistent prior) and better use of Burundi’s already impressive coffee infrastructure (the EU built the vast majority of currently operating washing stations back in the ‘80s). You can read more about specific initiatives in this post.

Private companies have also invested in better production practices. One of our partners in Burundi, Webcor, has an agronomist on staff who supervises an agronomic team to work with cherry producers on everything from fertilizer use to replacing old coffee plants with new ones (many of Burundi’s coffee bushes are between 20-60 years old; a definite hindrance to quality).

Just as important as improving the agricultural and marketing aspects of coffee production is the training of professional cuppers. If local partners don’t know what international buyers of specialty coffee are looking for, how can sales take place on equal footing? Again, USAID has invested in this area and one of its coffee specialists, Tharcisse Niyungeko, has been instrumental in both training and increasing the awareness of the importance of cupping for a coffee professional.

How Privatization has Benefitted Burundi Coffee

Actually, it’s too early to evaluate how the liberalization of Burundi’s coffee sector has benefitted those involved. It’s only been about four years since efforts began in earnest and I met with just a tiny fraction of the people earning their livelihoods from coffee. It’s pretty clear that it will take another five years or more before any widespread or significant consequences of this process will become evident. However, every single one of the 30 or so people I spoke with (ranging from government officials, to foreign NGO workers, to cherry producers) expressed that the liberalizing and privatizing of Burundi coffee is a positive thing. A very positive thing. From the producers’ perspective, the most significant consequence of allowing private players into the system has been competition. This new competition has led to several subsequent consequences: more transparency of the value chain, better and more connections amongst buyers and sellers (local and international), an actual choice in who to work with, since it’s no longer ‘the government’, amongst others.

Also commonly expressed was the conclusion that competition is good for quality. Producers are willing to be more selective in cherry selection and learn better agricultural practices if there’s incentive for them to do so. When the government controlled coffee production, cherry producers felt completely alienated from the selling of their own coffee – they characterized coffee growing as simply an exercise in producing something for the government to sell and benefit from. Since they had no idea how pricing was determined and coffee washing stations were 100% owned by the government, there was little choice or autonomy in how to work and with whom.

Thanks for reading,

Melanie

Go back to: Introduction Go back to: Part I

Note: The posts in this series contain both fact and opinions – from coffee professionals in Burundi and my own. Data collection for my master fieldwork has just been completed and has yet to be analyzed, so these posts will be updated as more information is revealed.

A Look Back on 2012 and the Coming New Year

Dear Collaborators,

It’s been quite a momentous inaugural year here at the Collaborative, thanks in large part to the support and enthusiasm of all of you. For us, it’s almost a year to the day when this project became a reality and so it is doubly appropriate that we now look back and reflect on all that’s passed and plan for the coming year. Without further ado, here is our look back on 2012.

Dear Collaborators,

It’s been quite a momentous inaugural year here at the Collaborative, thanks in large part to the support and enthusiasm of all of you. For us, it’s almost a year to the day when this project became a reality and so it is doubly appropriate that we now look back and reflect on all that’s passed and plan for the coming year. Without further ado, here is our look back on 2012.

Visits to Origin Partners

Our main aim is to facilitate long-term partnerships between roaster and producing partners and regular and frequent face-to-face visits to our producing partners are crucial to this process. Just as much for building trust and engaging in mutual exchange as to observe, learn and participate in coffee production of Collaborative lots.

Most of our trips this year were to gain a deeper understanding of the partnerships already established in the 10 countries we are currently working in. For most of these visits, we were present near the end of harvest in order to select the best the harvests’ had to offer. In the case of Bjørnar’s two-month stay in Guatemala, he was able to regularly cup day lots at Bella Vista’s wet mill and this gave him the unique opportunity to skim the “cream of the crop” of that season’s harvest. Also doing a two-month stint at origin was Melanie, who chose Burundi as the site of her fieldwork for her master thesis. At the same time that she interviewed people from all over the coffee sector about how “direct trade” is impacting the livelihoods of coffee producers, she met with and visited the people and coffee washing stations we have purchased coffee from. Burundi is a new origin country for us and we are excited about the potential of this developing origin with its recent focus on producing high quality specialty coffee.

During our most recent trip to Ethiopia, we spent two full weeks in the West and South regions of the country in order to become experts in these areas. Ethiopia, the birthplace of coffee, provides distinct and some of the most sought after coffees in the world and we are as in love as everyone else. Joanna and Robert toured cooperative washing stations we currently work with, met potential future partners and chatted with cherry producers about how coffee quality is determined at farm level.

Events

Just as important as meeting origin partners is meeting face-to-face with Collaborative roasters, current and potential. You drive the work we do. Your drive to obtain and provide better coffee is what inspires us to do the work we do. This is a community of producers and roasters. The goal is to close the gap between producers and roasters, so the collaborative aspect of what we do is foundational to the building of this community.

In London we cupped with some of London’s finest purveyors of coffee at Prufrock’s lovely café. The two cuppings hosted at Prufrock proved to be so interesting and successful that the Prufrock crew decided to continue hosting their own cuppings and involving us via Skype. At SCAA in Portland, we met with and cupped with producer and roaster alike. Robert participated on a panel discussion on direct trade at this year’s Nordic Roaster Forum. Finally, we hosted Le Carnaval du Café in Paris where leading experts and producers coming out of Brazil, Panama and Burundi presented on how varieties and processing techniques impact coffee quality. To round out and provide some context to these theories and experiences, participants cupped representative samples of the very differences in variety and technique that were presented on.

Most recently, Joanna and Robert flew to Korea to attend Café & Bakery Fair, an expo dedicated to presenting the latest and greatest of all things café: coffee, tea and bakery, with a heavy emphasis on coffee. Korea is a rapidly growing and interesting new market for specialty coffee. We were invited by our first Korean partner, Momos, who felt there were good opportunities for us to meet with roasters eager to work with high quality specialty coffee but currently lack access to these producers and their coffees.

Coming Up in the New Year…

Collaborative roasters have recently solidified their commitments for fresh crop Brazils (Carmo and Piatà regions) and Burundis. We are expecting these shipments to arrive in February. Check out our current list of offerings here.

We are finalizing plans for a January trip to Central America. This will be the first of (hopefully) many trips where we will be joined with Collaborative roasters who will meet the producers they buy their coffees from face-to-face! The tentative 10-day itinerary includes stops in Guatemala, Honduras and Panama. In February, Bjørnar and Robert head to Kenya and Ethiopia to finalize this harvest’s lots and to meet with current and potential partners.

We at the Collaborative Coffee Source would like to wish you a very Merry Christmas. May the New Year bring you success and excellent coffee...

Robert, Joanna, Bjørnar, Per and Melanie

Coffee with Seoul

So off we went, Robert and I, almost as far from Norway as you can get, to another small, coffee loving country - just on the other side of the world. Invited by Momos of Busan, we visited the Café Show expo in Seoul, did the rounds and caught up with the coffee circuit regulars, and then created a little event all of our own: a presentation about the Collaborative, attended by the specialty coffee roasters of Korea and a cupping, presenting the best of Brazil (Minas Gerais) and Burundi. If you have ever visited Korea you will notice many things to be different from Norway, or indeed anywhere else in Europe. Bowing is a good start. Passing things with delicacy and grace (and receiving them with even more) is another. Drunken businessmen asleep at the dinner table while their colleagues continue to eat is particularly noteworthy cultural norm. Kimchi. Cooking your own pork belly. Feeling like your living in a futuristic movie. But we were there for Coffee, not Gangnam Style re-enactments under subway signs.

We visited the finest coffee establishments in the land, Coffee Gong Jang, Momos, Coffee Libre, to name a few. The variety of brewing methods was impressive, (‘dutch style’ being the trend of the moment), the coffee was great, (although of course more darkly roasted than up here in the arctic) and the locations were at the same time predictably well-designed and surprisingly large.

After a day whipping round the Café Show in Seoul, we headed down to Momos HQ in Busan, Korea’s coffee port. Here snuggly nestled in a traditional building is Momos: rising several floors and spreading across verdant courtyards and dappled terraces, this café is a distinct destination.

We held a cupping and presentation at Coffee Gong Jang; a multi-floored industrial/cosy red and white extravaganza of a coffee shop in downtown Busan. Busan is the speciality hub of Korea, and the city’s coffee roasters turned out in force. With the help of Momos’ beautiful in-house polyglot Ines, we were able to communicate the Collaborative vision of trading utopia to the good roasters of Korea.

Yet despite the substantial investment, size and design of the coffee shops we visited, and the overwhelming interest from the roasters and baristas we met, we conclude that the coffee scene here is delicately blossoming rather than booming. Most coffee chains continue to serve impressively low-grade coffees, although this does not seem to hamper their rapid growth. The majority of coffee shops are closed during what we would consider as the on-the-way-to-work rush hour in the morning. They prefer instead to start later and stay open until the wee hours, providing a sensory sanctuary for the alcohol averse.

Interestingly, many roasters here also run training academies (from whence they gain the majority of their revenue) comparting the delights of cupping to the bubbling masses of coffee enthusiasts willing to pay for these services. Thus as we speak a handful more dedicated Koreans have learnt to decipher a good dark roast from a toast, single origin from a blend, fresh as a daisy from baggy and old. And here lies the future my friends. For soon these zealous Disciples of the Bean will be spurning the mainstream, and jumping, salmon-like, against the flow of mediocrity to buy only the best, create their own cafés, and roast their own coffee. And with a population of forty nine million and rising, South Korea is one to watch.

Joanna

Interview with Olivier Wege (Webcor)

During my two months in Burundi for my master field work, I took the opportunity to meet with our producing partners. The following is a conversation I had with Olivier Wege, Director General at Webcor. Olivier oversees 13 washing stations and Webcor's dry mill facility and we have bought three lots from/through them - two come from Webcor's Nemba and Masha washing stations and one from Businde washing station, which Webcor purchased from Icocoge. Because the Collaborative is about facilitating long-term partnerships between our origin partners and roasters, I wanted to find out from Olivier what sets Webcor apart in Burundi's coffee industry; why Collaborative roasters should want to work with him and his team.

Thanks for reading,

Melanie

Olivier: [Webcor] was acquired by a Swiss company in 2008 and when they acquired this company, there was a team of three traders. Coffee traders in the trading business for more than 20 years and then right after, they entered Burundi because in 2009, there was this privatization, so Burundi was selling some of [its] coffee industries, like washing stations, dry mill factories. So Webcor arrived in Burundi in 2009 and we bought 13 washing stations and we started building our own dry mill factory in the area of Ngozi/Kayanza. We bought those three washing stations…13 washing stations and so in 2010, was the first harvest. So the first harvest but also the first time that we have private [ownership]. Directly involved at the stage of the cherries and things like that; owning a washing station – that was the first time.

Because all the private and foreign companies were waiting at the door, at the export level but this was the first time that there was a new player so far in the chain. And the first year was quite complicated because everybody had to understand the new system, how are we going to proceed and etc. So we had this whole system that used to be there with the state and then the new system… So in 2010 and 11 was a transition phase. It was quite hard for us, so we went through a lot of issues: political issues. A lot of communication problems between different partners and etc. and actually, we are still…we are now in and things are now quite calm. People now understand that the system has changed.

Now we have more private – a more private campaign, so we are really into a new area for this Burundi coffee industry. And so this is how Webcor has come into the coffee…the Burundi coffee industry but right from the beginning, we had…the way that the whole project was thought. So we have, we managed to have a good team because the idea was to really to go to this specialty coffee because we are first [in the] Ngozi/Kayanza [region] – it’s really the best area if you’re looking for the best coffee. And so our washing station[s] are from there and now when you have the right location, you have to have the right people and we managed to have the right people and have an agronomic department which is not really…it’s quite unusual in a commercial company to have an agronomic department because this is the state or…this is the state affairs but the commercial company…we chose this [model] to have control because there are many issues – the quality or the productivity of the coffee in Burundi.

So we want to make sure that the right things are met. So that’s why with our agronomic department, we can work with people like Tharcisse and Emile, with the project they are trying to put on. And that’s what we are doing: we are trying to work directly supporting the farmers. Making sure that at least the area where we are located, make sure that all the agronomic issues are followed. And then this is the only way to make sure that the productivity can grow and that we can keep on the same quality or even growing better.

And participate in some competition, like Cup of Excellence. Last year there was this Burundi Prestige Cup and then in 2012, it was the East African competition. So this is a way to show people that we are not here to just make some money, we came here to make sure that we have the quality and we make sure we keep on the quality. That’s why we are participating on these competitions and the first competition in which we participated in 2010, we had the first prize. Last year, we didn’t have a lot of coffees, so we didn’t have a very good position and this year, with the Cup of Excellence, we came back to a good position.

So this is our [mandate]: to focus on productivity and quality and make sure that we keep on this point.

Melanie: So if Webcor started working with coffee in 2008, why did they decide to enter into it from the specialty standpoint rather than just commodities?

O: We do both. Burundi…this is the strategy for Burundi. But we do both. So when they bought this trading company, they bought all the business, so the team was already buying a lot of coffee from Latin America, from Asia but few coffees from Africa. And the idea was really to strengthen the business from Africa. And on Arabica. Because this is where they felt the trend was – Arabica, fine coffee. And that’s why we came to East Africa. And then actually, we bought this entities in Burundi but we are also in Rwanda, we also in Uganda, Ethiopia but Burundi is kind of the first step. We put on, we are trying to put on business models that we are going to replicate in those countries.

M: And why did Webcor choose Burundi as the first?

O: Because the opportunity was there at the moment. Because in 2009, there was this privatization and then the [opportunity] came at that moment. So the idea was to find Arabica coffee in this trade, in East Africa and Burundi there was this privatization at this moment. So that’s why we started in Burundi but since it wasn’t so easy, because we had a strategy and the first year was to enter Burundi and then Uganda, etc. etc. And then finally, it happened that it was not so easy to enter a country and then especially when the system is changing and everything. So what we decided was to really focus on Burundi and make sure that everything is well understood and then we go step-by-step.

M: So is the agronomist that works here, is he the only agronomist? Or does he have a team?

O: He has a team. So he has three agronomic technicians. He is himself an engineer, he has three agronomic technicians. Why three? Because we have three regions. Washing stations separated in three regions. And then when necessary, we used to have…the first year, we had the…2010 and 2011, we had a team of 70 agronomic monitors. So people on the field are going around and making sure that… Finally, it wasn’t so useful, so we decided to refocus on these three technicians. And then making some partnerships with local entities.

M: Like cooperatives? Or…

O: Exactly. What we are looking for is making groups…it’s a kind of cooperative. But the name of cooperative in Burundi because in the past they had some issues, so when we say cooperative, there are sometimes…farmers, they don’t like this name. So we say groups of farmers, associations…

M: But they’re independent.