THIS BLOG POST IS THE SECOND IN A THREE-PART SERIES. READ PART 1, AND PART 3.

In Part 1 of this blog series, I wrote about La Palma y El Tucán’s (LPET) impressive social impact.

In this blog post, the second in a three part series about LPET, I will dive deeper into the strict methodology and innovative processing behind the stellar cups that have earned LPET an impressive reputation for quality.

A quest for quality

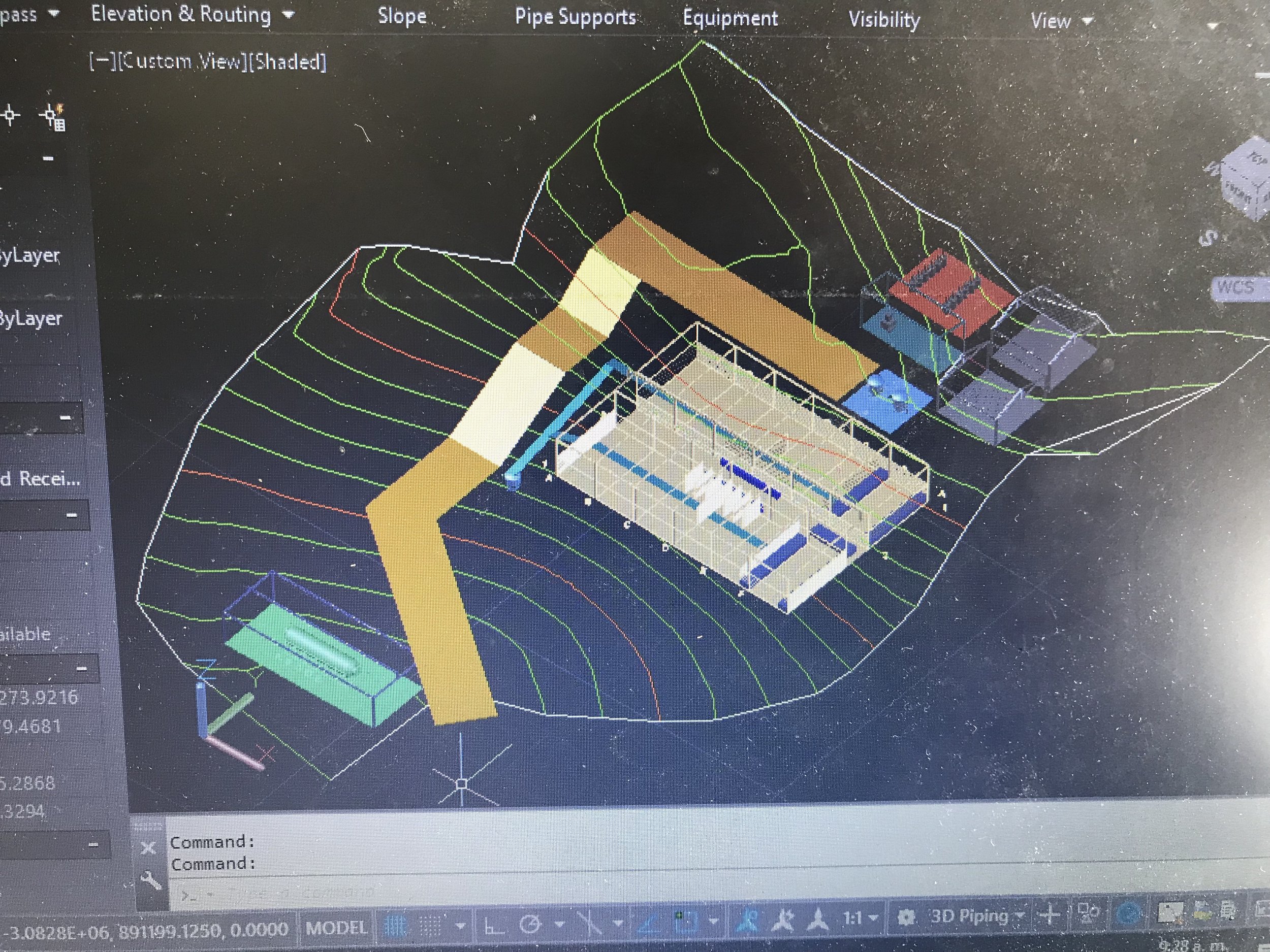

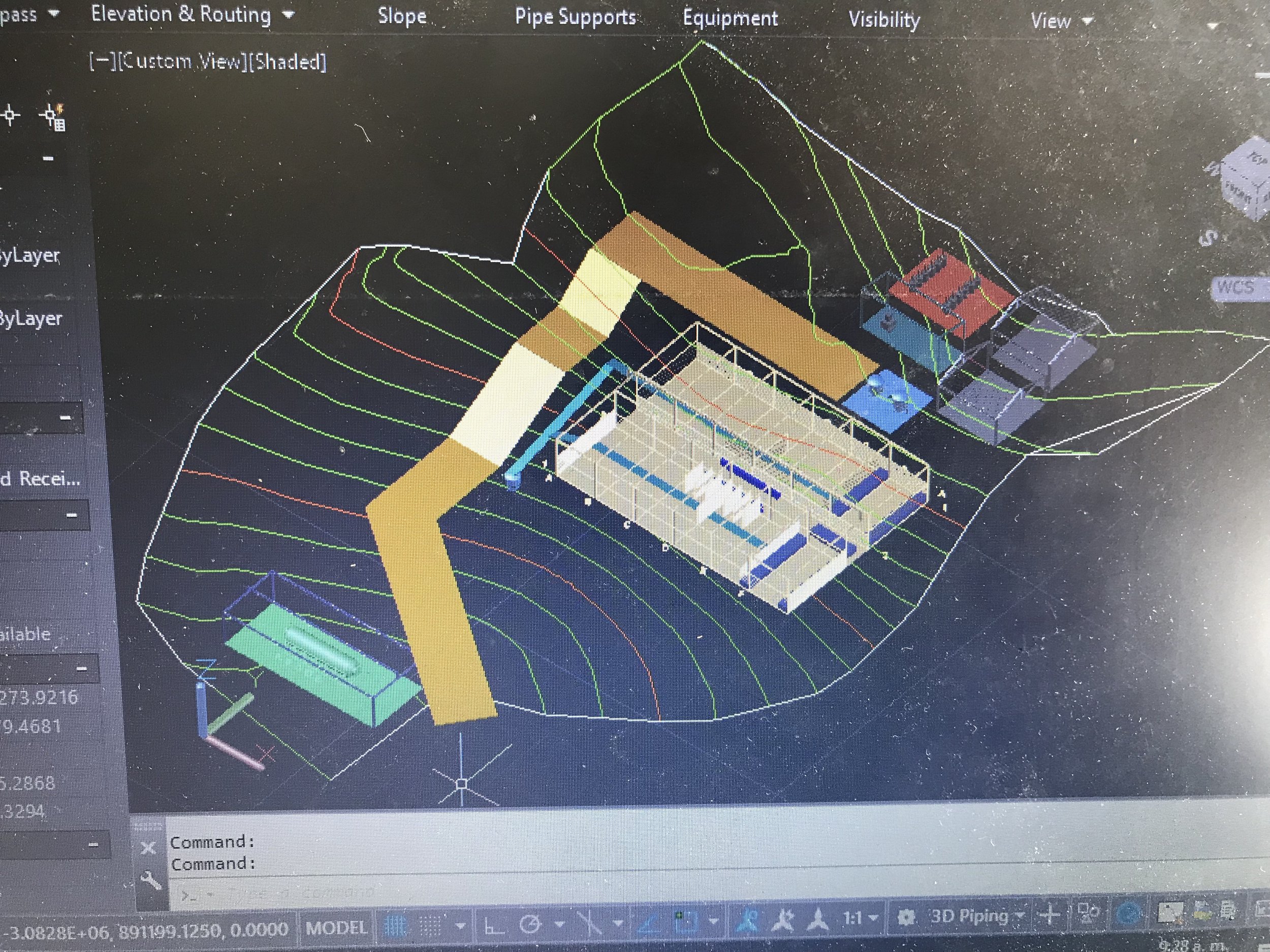

When LPET began in 2012, the founders, Felipe Sardi and Elisa María Madriñan were convinced that varieties like Castillo, known for their disease-resistance, but not for their cup quality, had the potential to produce delicious lots, if they were picked selectively and processed well. Starting a farm from scratch meant that the pair could design both the processing facility, and the methodology, with quality as the number one priority. This is the vision behind LPET’s Neighbors & Crops program (N&C).

To ensure perfect ripeness, the cherries destined for the N&C lots are picked by LPET’s own team of highly-trained women who select only the ripest cherries. (The deep cherry-red nail polish they wear helps them identify the perfectly ripe fruit!) The cherries are then transported by truck to the LPET farm for processing.

Receiving the cherries at the station

Due to the very small size of their farms, a single N&C producer is unlikely to produce sufficient cherries in a single day to fill a ten bag lot, so lots are usually composed of cherries from five or six different producers. The lot will keep the name of the producer who has the most cherries in a single lot.

Checking the pH of the lots.

Measuring the Brics

Adding rigor to research

Each lot will be tracked and recorded. At the farm gate an LPET team member notes the weight of cherries. At the station gate they measure the pH and sugar content. All this information is recorded on a physical tracking sheet for each lot, and transferred to a spreadsheet. This is essential data which they can use in the future. For example, this year the team reviewed every cupping sheet for the lots they produced in the last five years. They identified the best lot for cup profile and scores, and noted the relevant data including brics, pH, and time spent fermenting. With this data they created several “recipes” which they applied to cherries delivered this year. If you get a chance to cup the incoming fresh crops from LPET, you will understand the positive impact this rigorous approach has on quality.

After the cherries pass the quality controls, they will undergo lactic pre-fermentation, water sorting, depulping, fermentation, washing and drying. To share all the details of these processing method is a blog post for another day, but we can at least tell you about their star process: lactic fermentation.

Tracking the coffee through the quality process

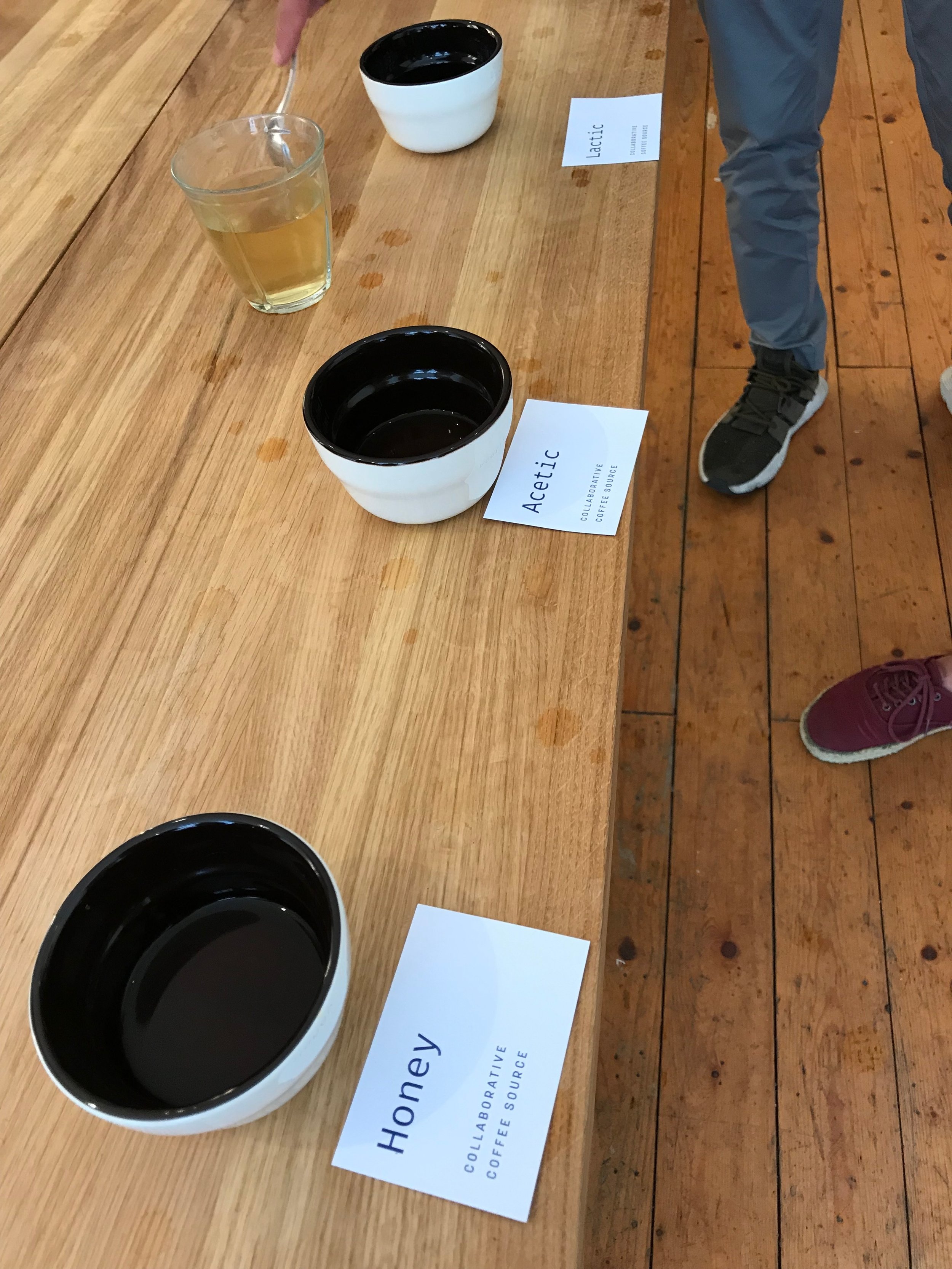

What is LPET Lactic Fermentation?

LPET lots show extremely diverse cup profiles. From a juicy tropical punch to a rum raisin syrupy shake, they can fit all preferences and curiosities. This is due to the extremely “picky-picking,” the state of the art equipment of their processing facility, and the knowledge of the whole team. Additionally, a large chunk of credit must go to this innovative Lactic process they have mastered over the years. A unique acidity structures each lot with its milky or winey tones, bringing a heavy body and a sparkling touch to the cup.

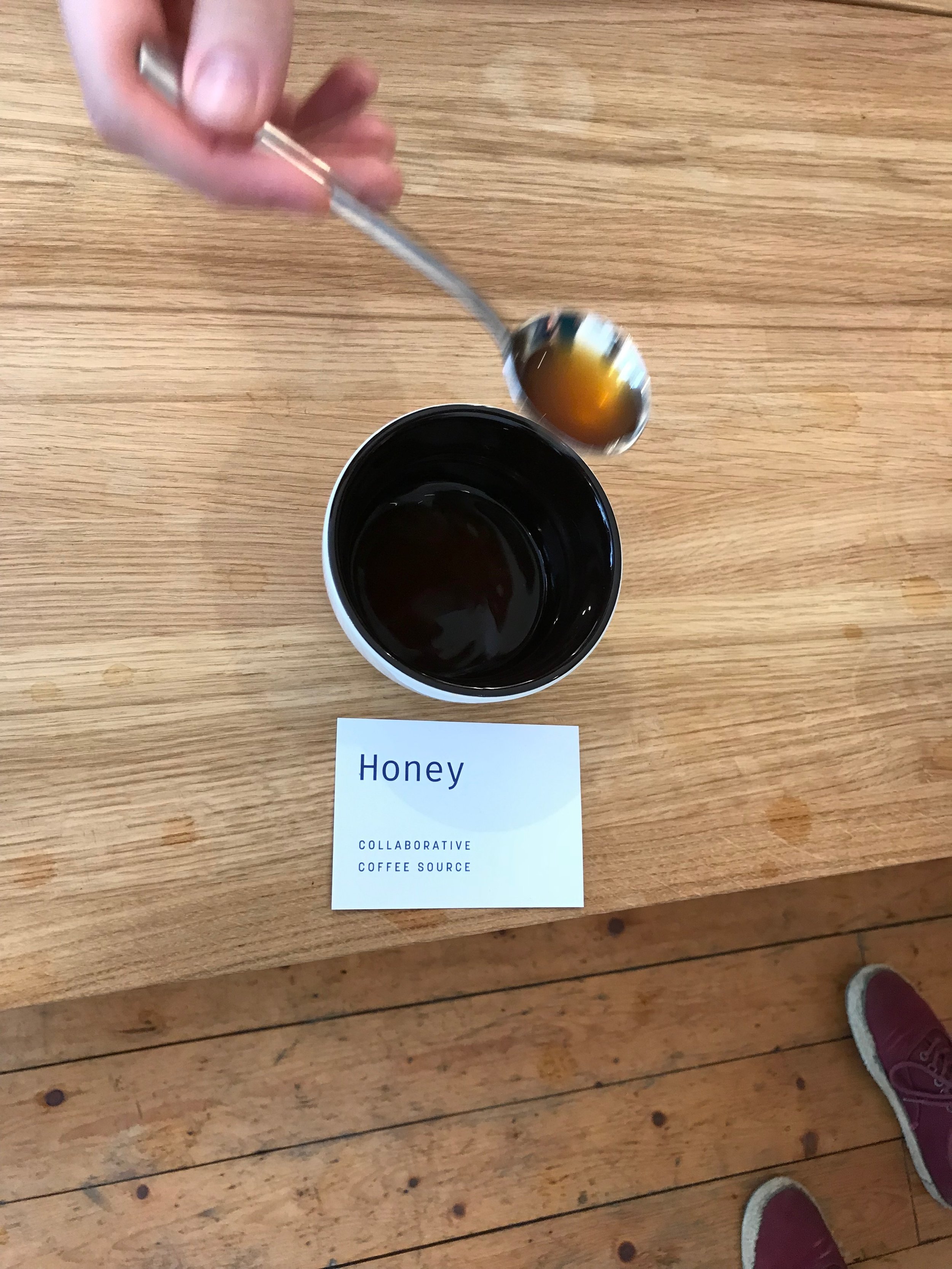

Sweet cherries ready to ferment!

Before depulping begins, cherries are placed in a closed tank. Sugar content, temperature and pH are noted. The high sugar content of the perfectly ripe cherries provides ample food for yeast and bacteria naturally present in the air and on the cherries, so fermentation begins. One by-product of this fermentation is carbon dioxide. As the tank is closed it will slowly fill up with CO2 and the air will be chased out. Under these anaerobic conditions (meaning without oxygen), the bacteria that survives will produce lactic acidity, hence the name. For Lactic Fermentation, LPET will leave cherries fermenting in tanks for approximately 70 hours before depulping.

An easy way to see if cherries have been through a lactic fermentation is to look at the beans after depulping. If everything went well, a bit of alcohol was also produced during the fermentation, transferring some color from the pulp to the beans.

Lactic fermented beans after depulping

The quality control is not finished yet. After drying and milling, each lot, be it a Neighbors and Crops micro-lot of 350kg, or a Heroes Series nano-lot of 25kg, is sorted again by hand with the objective of achieving zero major and zero minor defects. Perfection is always the goal.

Final hand sorting

All of these sorting steps give us an incredible ratio of cherries to green of 1:8,5. On average, LPET needs 85 kilos of cherries to produce ten kilos of green. Think about that on your next sip!

Innovation never stops behind this farm’s doors, ambition to improve is always carrying them forward. We are more than happy to chat to you about this project by phone, or over a coffee when we see each other somewhere on our beautiful home planet.

This season, we have fifteen stellar lots for our customers in Europe. The first ten lots are ready to go and will arrive in Hamburg early December. Five additional lots from the late harvest are being processed as I write this. Expect those around February 2019!

Nine lots have been already booked so hurry, before they all go. To book your LPET Neighbors and Crops lot, contact me at nicolas@collaborativecoffeesource.com !

Cheers – Nico

Read Part 1 of this blog series here.